Factory sourcing for fashion manufacture course - how to find a production partner

A lot of new entrepreneurs struggle to find a suitable factory for production + aren't sure where to begin looking. This post takes a look at how I can help you to find a manufacturing partner...

If you saw my blog post on Friday about factory sourcing, you'll know that it's a tricky subject + just because one factory was great for someone else, it doesn't mean they'll be great for you (you can read that post here if you missed it). You may remember that I mentioned I offer services to help clients, usually who are new to the industry, find factories. There's a few options to suit different needs + budgets + I can help with some training + guidance on approaching factories yourself, I can find some suitable options for you, or I can provide a mix of both.

Unlike other companies offering factory finding services, I don't take any royalties or expect anything else from you. Other companies usually get money from the factory (which means their information can be biased), or they don't give you the factory name + you're required to place all orders through them (which means you pay up to 20% commission on everything you make, essentially forever which can cost thousands, as you are never given the factory details). I don't receive any commission from anyone, so I'm able to be impartial + make an unbiased analysis of the pro's + cons. You're also free to work with the factories however you choose, I give you all of the contact details so I don't have to be involved at all.

All of my packages include consulting time, so that you can get all of the information you need + you also have the opportunity ask any questions you'd like to have answered by an industry professional. I work with clients worldwide + am able to arrange a call time that works for you + your time zone. I can call any phone, so you don't need to have Skype or any special equipment or software, just a phone!

Service #1 Help you to approach + work with a factory

This option is best for those on a limited budget, as it is the lowest price + gives you the knowledge to go out + approach factories on your own. It includes consulting time in which I provide training on where to start looking for factories, the best way to get in touch with them + things to ask. We'll also cover things to look out for, that might be an indication that the factory isn't a good option, as well as how to respond when you get a positive reply from a manufacturer. The call is tailored to your situation, so you'll receive personalised information.

After the consulting session, you'll also receive notes from the call, so you don't have to worry about making your own. I'll also include any links and/or resources that will be relevant to your situation. As well as the notes, I'll also send you a copy of my simple Excel template, which helps you to track responses + compare your options.

Service #2 Help you to approach + work with a factory (extended)

The extended version includes everything in #1 + some extras. This is for people who would like a little more support with supplier sourcing. After we've had our first session, clients go + research factory options, based on the training they received from me. When they receive replies from suppliers, they send them on to me for review. I can review up to 5 factory options for you. When this is complete, we can have another consulting session to discuss the options, the pro's, con's + further questions that need to be asked (if applicable), or next steps to take.

Service #3 Factory information + sourcing help

#3 is a separate option to #1 + #2 + is best either for those wanting the most help, or those who don't have much time. Finding a factory does require a lot of searching, emails backwards + forwards + often patience. Many of my clients are working on their fashion business part time + have other commitments such as jobs + a family + simply don't have the time to be chasing factories. This package includes consulting time to go over your needs + what you're looking for in a supplier. I then go + start looking for + emailing suppliers. As I'm dependent on how quickly the supplier can get back to me, this usually takes a few weeks, but I keep clients up to date with progress. I put my findings in an easy to use Excel file, so you can easily compare the options, but we'll also discuss the pros + cons of each. You'll also get notes following the call so you can go over the information at your leisure. This service gives you all the information that you need to make an informed decision about which supplier option is best for you. As I mentioned in my previous post, as a lot of the success of a supplier partnership is down to the relationship you build, I provide information for you to make a decision with, rather than tell you which one to go for as I believe this leads to better results.

You can learn more about this option, here.

I hope this has helped you with some info about how I might be able to help you. If you're not quite sure which service is best for you, or if you're not sure if I'm the right fit for you, I'd be happy to answer any questions you have in a free call. You can book a 'free 15min enquiry call' via the link below + I'll phone you at your preferred time;

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

Sourcing manufacturers for fashion; why there isn't one factory to fit all

Lot's of customers ask me to recommend factories, or ask which is my favourite. There's lots of things that contributes to the success of a supplier relationship, which I talk about in this blog post....

I get lots of emails from people, some who I've done a bit of work for, others that I've never worked with, asking me to recommend a factory. The truth is, there's so much that goes into selecting a factory that it's not possible to just give out a factory name that you can confidently recommend to anyone. There's so many things that you need to know before starting to look at factories, the most important ones being how much you want to pay (please don't talk to a factory without knowing your target cost price (knowing but not telling them), it will not end well!), how many items you will make and garment specifics (tech packs). From there, you can start to approach + shortlist potential manufacturing partners. There's not usually one perfect option, especially if you're a small business, so it's then a case of deciding what you're willing to negotiate on, it might be the level of detail, price, number of colours, etc. Personality + the relationship you build also plays a crucial part in the success of the partnership. This is why, when clients work with me for manufacturing + sourcing help I give information about the pros + cons of factories I talk about, rather than my personal preference. People have different ways of working + some types of communication work best for some, but not others.

To explain what I mean further, I'm sharing some real life examples with you. For the privacy of the people/labels involved, I've changed their names, but the situations are actual events that I've witnessed during my time in the industry. These show how although a supplier may be great for one person, they might not be for others.

Scenario #1

A few years back I worked at the head office of a Womenswear retailer. As a buyer, one of my jobs was to organise the manufacture of our labels, which included card hangtags with our branding + barcodes + woven labels with the size on. The company had been working for the same supplier for years + I'd been dealing with them for 3. We built up a great relationship + even though ours was a fairly small brand, I got super fast help, great quality + competitive pricing. They were happy to do me favours at short notice + do all sampling for free. On the personal side, even though we never met in person, we got to know each other really well, with the supplier even sharing amazing photos of Chinese New Year + other events they attended with their family. All sounds great, right? Someone worth recommending? Well, when I left the company, my replacement Karen worked very differently to me. Karen didn't make the time for niceties + didn't take a collaborative approach (which for me, was one of the best things about this particular supplier). She made demands, she didn't take the time to understand what the factory capabilities were, or what the staff did exactly. This approach had done really well for her at other brands, where the suppliers expected blunt, direct information, but this didn't suit the label supplier. I still keep in touch with colleagues at this company + unfortunately, after a few label related disasters (yes, they really exist. Especially when the black label dye runs on white shirts), the companies parted ways. Karen then found a new label supplier that suited her style of business + has been much happier with their performance.

Scenario #2

When I was working with a high end designer we were struggling to find a new manufacturer at short notice, after the one we had been using closed down. Fortunately (or so it seemed) my boss was friends with a lot of people at other labels, who were happy to share information with her (very rare in the fashion industry, but they had been friends for 20+ years). They recommended a factory to us, that had been doing really well for them + had been manufacturing similar products to us. We immediately ordered a few styles from them + development was going well, but then after the final order was confirmed things really slowed down. Their communication became bad + the timeline was way behind. How could a factory that did so well for one company be bad for another? In this instance, it came down to order size. The other label was ordering lots of styles at 1000+, whereas we only had a few styles + ordered around 300 units. We hadn't built enough of a relationship with the factory to become a priority + our small orders made us insignificant compared to other customers.

This can happen a lot with small labels in particular + you have to work extra hard to build the relationship + show the factory you are serious. If you're able to do this, the factory can see that there's potential for more orders + will spend the time on you + your products. If you're not putting in effort, or not giving information the factory needs, they won't take you seriously + therefore won't make you a priority, which can lead to poor quality + delays.

Scenario #3

Coincidentally, I have several clients using the same factory at the moment. Surprising really, as the clients had already selected a factory before they worked with me + given how many suppliers there are in the world, it's amazing they all chose the same one! One client, let's call her Caroline, is getting amazing results from this factory. After a lot of backwards + forwards at the start to iron out all of the details + make sure everyone is on the same page, sampling + production has gone smoothly - the quality has been good + delivery is on time. Meanwhile another client, for this, we will call her Julie, has been waiting months for samples. Julie was excited to get started + didn't take the time to outline her expectations from the beginning, so since I've been working with her we've had to go back + look at things like acceptable quality + delivery timelines. Because Caroline worked these things out at the start, the factory knew what they needed to do + when to do it. Meanwhile they were confused about what Julie wanted + when she needed it, so other clients got ahead of her in the production queue. This can often happen if you're unclear about your deadlines; factories will prioritise clients who have a clear delivery date + are following up on samples. If you have a relaxed approach, you would be waiting a long time for samples.

If you want to learn more about working with factories, I have a free Masterclass, ‘How to Get your Fashion Ideas Produced, without wasting your time and money’. You can click below to register free!

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

How I started my fashion business with a tiny budget | Start a fashion brand on a small budget

Starting a fashion label on a small budget is possible, if you know how + are willing to put in a lot of work...

Over the years, many people have asked me how to start a fashion business with no money. There's several things that set me apart from other fashion business consultants, one of which is the theory behind your budget. You've probably heard people say that you need £20k to start a fashion business and the truth is, you really don't have to spend tens of thousands. How can I be so sure? Because I didn't. Sure, I didn't experience massive sales at the start, or overnight success, but I did create a business that could eventually support me full time, with happy customers and stockists worldwide. And I achieved it with just £150 (around $190US) from my part time job.

Now, at this point you're probably thinking, 'but you have a fashion industry background, so you could probably do loads of it yourself without spending any money' and while yes, that is true, there's still ways to make a start with a minimal budget and no experience. I’ve had clients who have been able to launch for hundreds, not thousands. Also, everyone has different strengths and weaknesses. Yes, I could make samples myself, but I didn't know the first thing about social media strategy or writing product descriptions when I started out, which many others can do themselves easily. This post explores some of the ways you can make a start on your business without having a lot of money in the bank.

How I started my business and how you can too

If you're on a small budget, your strategy is of course very different to those with more cash. Any ideas of factory production, glossy lookbooks or fashion shows have to go on hold for now. By starting small, you can minimise the financial risk (which is of course great), but do keep in mind that it will require a lot more effort on your part (and starting a business is already hard) and progress will be much slower in general, so don't have any ideas of quitting your day job anytime soon.

Here's some of the methods that I used to start my fashion business with very little cash, which you can use too;

Use my signature VSP Launch model (Validate - Sell - Produce, so you don't have to buy stock in advance)

Learn as much as you can, particularly about free types of advertising (including social media), website building and sewing/fabrics - there's a lot you can learn on my website for free.

Don't be tempted to spend a fortune on a website, fancy computer or software, to begin with you can get by with the basics if you have to

Start small, with a limited number of options; I started with 2 styles

Enlist the help of willing friends and family; more often than not they want to see you succeed and are more than happy to help. For example, I borrowed a camera from my Dad (in the days when camera phones were awful - nowadays a smartphone can do the job and chances are you have one already!), a friend helped me with writing descriptions (not my strong suit) and a group of friends helped me to refine design ideas.

Collaborate, this one was especially helpful; I worked with other people who also wanted to start a business and had a similar style to me, but a different offering. For example, I worked with models, photographers and make up artists - we all worked for free, but in exchange were getting professional quality work (I provided the products for the photoshoot) that we could use on our social media and websites. Also, we linked to each other online, to get exposure to a new audience, that had similar interests to our businesses.

The importance of planning

As with all types of business, planning is key and in this case it's especially important to make sure you know where you want to take the business and what you want to achieve so that you don't waste money on things that aren't essential. We’re starting a fashion brand on a budget, remember, so we need to make every penny count!

It'll also help you to reinvest wisely, so that you can grow your business effectively. Key things you'll want to decide on in advance are;

How do I want to grow my brand? For example, will you spend your time growing your Instagram following, working on getting press features, maybe you want to get your products into boutiques?

Do I want to have exclusive designs, or would I be happy customising existing styles with my own prints (this is an especially good option for anyone wanting to start with t-shirts, sweatshirts, activewear and other casual products, but it can work for other products too)

Do you specifically want to start with clothing? Accessories can often be a much easier way of starting, as you don't have to consider the fit and one size fits all in many cases, so you don't have to worry about picking a size range. The number of returns are often less as well, because people won't return due to the item not fitting, or not suiting them.

I recommend being specific with your offering to any startup, but especially to ones with a limited budget. Don't try to offer lots of options on everything, as you'll need at the very least a photography sample made for everything and the more items you have, the more you’ll need.

Scaling up

When you've made your first few sales, you can then look at reinvesting the money you've made on that. Ideally, if you're able to support yourself with a full or part time job, it's best to invest most of the money you make, so that you can speed up your growth (keep some in the bank for any unexpected expenses though). Listening to customer feedback is really important and this can cover everything from actual comments that you've received, but also things like social media comments or, the most important one of all, the sales data. Look at what your most popular size, colour, style, etc have been and use this when making choices for new products.

I hope this post has been able to reassure you that anyone can start a fashion label, no matter what your budget is, as long as you're willing to put in the work!

💌 Love this kind of no-fluff, high-value advice?

Then you’ll definitely want in on my weekly newsletter - Designer Diaries. It’s your behind-the-scenes pass to growing a fashion brand without the overwhelm. Think bite-sized strategy, creative inspo, and the kind of real talk your business actually needs.

👉 Click here to sign up free and get it straight to your inbox every week.

Why it's Important to Know Your Target Audience - Feature on the Biz and Bubbly Blog

I'm delighted to be featured on Biz + Bubbly, one of my favourite resources for female entrepreneurs. I talked to founder Morgan about target customers + why they're so important....

Last week I was delighted to announce that I'd been featured on Biz + Bubbly, a wonderful resource for female entrepreneurs with great tips on growing your business. It's particularly helpful for understanding aspects of marketing, such as social media, SEO + EDMs. If you follow me on Instagram, you'll also know that I did a stories takeover + did a video feed about the topic of the blog post I'd written - 'Why it's Important to Know Your Target Audience'. I'm not going to lie, I found the video rather terrifying as it's something I rarely do, but as I got into it, it was fun + an easy way to share information.

If you've been following me for a while, you'll know that I really value the importance of the customer + understanding the target audience is the very first step any new business should take. The post I've written for Biz + Bubbly covers why this is, what you need to know + how to use it. You can click here to read the full post if you'd like.

I'd love to hear your thoughts on this, or any ideas you have for future blog posts. Feel free to leave a comment below, or send me a message here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

Basics 101: Where To Start When Building A Fashion Brand - feature on The Fashion Conversation

I've collaborated with 'The Fashion Conversation' on their latest post; Basics 101: Where To Start When Building A Fashion Brand....

I'm so happy to announce that today I've been featured on one of my favourite websites, The Fashion Conversation. If you're not familiar with it, I'd definitely recommend having a look, as it focuses on emerging fashion talent + is a great way to keep up with what's happening in the industry. Their Instagram account is full of stunning fashion designs + well worth following.

I've collaborated with them on a post called 'Basics 101: Where To Start When Building A Fashion Brand', where I've shared 5 steps that will take your business from daydream to reality. You can read the full post on The Fashion Conversation website, here.

I'd love to hear your thoughts on this, or any ideas you have for future blog posts. Feel free to leave a comment below, or send me a message here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

Mistakes to avoid when starting a fashion brand; why you shouldn't cut corners in business

Lately, I'm seeing so many new entrepeneurs struggling with production, because they cut corners during the early stages of their business. Learn how to avoid making the same mistakes....

It's not often that I get frustrated, I'm generally very calm + collected, probably because I have a contingency plan for absolutely everything (for those who've seen Prison Break, think Michael Schofield). So, it's quite surprising that today's blog topic comes out of frustration! You may know that I do a lot of 1-on-1 coaching sessions, often with new entrepreneurs. One of the main things we talk about is planning, not rushing things + generally not going full steam ahead with a new business plan before you've really thought things through. It's hard, I know. You're excited, you want to get those ideas + designs up for sale now. But this isn't a 'get rich quick' scheme + it's certainly a marathon not a sprint. I've been trying to help a number of clients lately who I'd not worked with before, who were having various issues. I thought I'd share those stories with you today, as they are great examples of why you should take things slow, make a plan + do as much research + preparation as you can. For the privacy of the clients, their names + the product type has been altered, but the situation + outcome is the same.

Mistake #1; no contract

A new client came to me a few weeks ago, who was extremely worried that she'd been caught out by fraudsters. For the purposes of this article, lets call her Ellen. Ellen had designed a range of clothes + had some professional drawings done, but had opted not to have tech packs or a contract drawn up, as she thought they would be too expensive. Tech packs + contracts go hand-in-hand, as you can set the 'quality' expectations in your contract to be based on what you've approved in your tech pack. If you're not familiar with tech packs, you can learn more about them here + how to use them to hold a manufacturer accountable. Instead, Ellen handed over $3600 (approx £2700) to the factory for 10 samples + patently waited for them to arrive (she'd been quoted a 2 week turnaround). She waited + waited + waited. 12 weeks later, she still hadn't received any samples + the factory had been totally unresponsive to her messages, simply saying that things were delayed and she had to wait. The majority of her items were basic t-shirts, there's no way they had a legitimate reason for the delay. That's when she called me in + I wish I could have helped. Without a contract, or any proof of what's been agreed, or a receipt to show what the money was for, there's not really anything anyone can do.

Lesson learned; always have a contract in place for any services that you pay for + ask for a receipt which details the amount paid + what it was for. Ellen's strategy to 'save' by not having a contract or tech packs (which would have cost approx £350-£500) ended up costing her over £2700 in money lost on samples.

Mistake #2; No tech packs

It honestly astounds me how many people decide to go ahead with production + don't have a tech pack. I'm so passionate about this that I'm currently recording a free video training on the subject! Customer number 2 that contacted me recently, let's say Luisa, opted against having a tech pack done, so that she could save the £35 tech pack fee. She got in touch, as there were a lot of problems with the sample she received from the factory + wanted to know how to approach getting the sample remade free of charge, due to the errors (many factories charge for samples if they've not worked with you before. In this case Luisa was charged $150 for sampling, plus a $22 courier charge). I spoke to Luisa + we talked about what she was unhappy with. For example, the sample wasn't lined, it used a metal clasp instead of a plastic one + the measurements were way off what she was expecting. The problem is, none of these features can be understood from a drawing. How would the factory know it was lined, the picture would look the same lined + unlined? How would they know to use a plastic clasp? + if they've not been provided with measurements, how can what they've provided be wrong? Not sending a tech pack is like giving the factory free reign to do whatever they feel like. If you have a good factory, you may end up with a nice garment, but not what you're looking for. Worst case scenario, the factory do whatever is easier + cheaper for them, not what's best for you + you end up with something that's completely unwearable. That's exactly what happened here + unfortunately, we couldn't ask for the next sample to be free, as a sample can't be incorrect if you didn't give any direction in the first place. So instead, Luisa started again, this time with a tech pack.

Lesson learned; think about it, if you received a drawing of something, what are the chances that you would guess the right measurements, fabric, trims, fastenings? That's why tech packs are so important, because they take the guesswork out of the process. So in this instance, Luisa thought she was saving £35 by not having a tech pack, but in fact she ended up spending an extra $172 (approx £130) on starting over with the samples.

Mistake #3; No planning

I'm going to choose the name Karen for my next example. Karen had a beautiful range designed that she wanted to release in October, with plans to sell it for the Christmas party season. She got in touch with me as production had been delayed + she wanted to ask me what she could do to get things back on track. In reality, it transpired, things were already on track, it was actually that Karen hadn't allowed enough time for production. I'd say on average the start up collections I work on take around 6-8months from start to finish, with some taking even longer. Karen had only allowed 3 months to make her collection, which meant that she was massively short of time. Unfortunately, there's only so much you can do to speed things up, so Karen is now left with the choice of either cancelling the range and loosing all of the money she has spent on samples (hard to say how much exactly, but I would imagine over £1500), or continue with the collection + release it after Christmas, which will mean it is much harder to sell given the styles she has + the marketing strategy she had in place.

Lesson learned; good planning is the key to a successful production run. Make sure you look at all of the steps you need to allocate time for in advance + allow an extra buffer for any delays. In this instance, it's likely that failing to invest some time + as little as £25 in the 'quick start guide to planning + producing a fashion range' has cost Karen over a thousand pounds.

Don't make the same mistakes these people did, make sure you don't cut corners, plan effectively + add a little extra time + money in the budget in case of any unforeseen circumstances. There's lots of free articles on the blog to help you + you can always ask about 1-on-1 help via the contact page, here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

What do I invest in to help my clients?

You might be surprised to learn that each year I invest thousands of £ + hundreds of hours on expanding my expertise + contacts to help my clients....

If you've been following along with the blog, you may be aware that I'm in Germany at the moment, having attended the Munich Fabric Start fair last week. This trade show was a good opportunity for me to meet fabric, trim + label suppliers, as well as manufacturers + some very informative seminars on topics relevant to fashion business + production. I attend several events each year + spend thousands on travelling to meet suppliers, trend information + education on the latest industry updates, so that my clients don't have to!

If you've visited the 'work with me' section of this website, you may have noticed there's a few different options to choose from. You can work 'a la carte', meaning you simply cherry pick the exact services you need + I'll work to your requirements, or you can select a package. The packages have been designed for specific needs that a lot of my customers have. For example, some are starting from scratch, whereas others already have design ideas + just need technical help. The pages are tailored to those scenarios + offer lower rates than the a la carte pricing + have also been tested to ensure that they provide a solution to your particular need.

It doesn't matter if you choose 'a la carte', or a package, everyone I work (or even, anyone who subscribes actually!) benefits from the investments I make in research, education + networking. For example, if you choose to work with me on designs only, even though we don't have a consulting session on the phone, you'll still benefit from the insider information I have, for example, because I'll select upcoming trends that are relevant to your customer, or I'll suggest fabrics that are available at your price point. This is also a good time to mention that the more information you're able to provide (I send a short questionnaire to all new customers), the more I can tailor any work I do, specifically for you + your customer. Best results usually come from people who have taken the time to give me as much information as possible on what they are trying to achieve!

Another good example of this is tech packs. If I'm working on your tech packs, a lot more goes into it than me simply filling in information. A lot of consideration goes into each section, so that the tech pack is not only factory + sampling ready, but it also makes the most of current methods, fabrics + practices, to make the sourcing + production process as simple as possible.

Attending a showing of a fashion collection + viewing other ranges to see how the industry is working

Swatch cards that I collect from suppliers to help clients make informed fabric choices

From my experience, working with a consultant has always been worth it. I appreciate that most businesses want to keep costs down, but after having seen the benefits of having a consultant, I can see why this is a worthwhile investment - in fact I now have 2 consultants! One who specialises in systems for websites + emails + another who helps with getting traffic to my site + customers through the door. Although those consultants are a cost to my business, the cost would have been even greater if I hadn't implemented any systems, or got any traffic (+ therefore customers!) to my site. I mention this because, as you may know I also offer consulting for the fashion industry + one of the most common misconceptions that people have is that they have to spend tens of thousands of £ or $ in order to start a fashion business. You can if you want, but I certainly wouldn't consider this a requirement, in fact, back in 2010 when I started my fashion business, I only had £150 to work with. Of course, this is a much slower approach, but I was still able to grow a business that shipped to customers worldwide, was stocked in stores on 4 continents + had features in magazines - so it is possible to start with a smaller budget. By knowing the best places to invest your money + how to approach manufacturing you can save yourself a lot of time, stress + money.

One of the things a lot of clients need help with is finding a suitable manufacturer. I've designed a specific package for this, so that I can offer the best, most relevant help to those customers. There's an upcoming post planned around factory selection, but essentially when choosing a factory, this is very much a decision that has to be tailored to your personal circumstances. There isn't a one size fits all approach to working with a factory, as some will work better than others for one particular business + what one company might consider a 'bad' factory, is actually perfect for another. For this reason, I've been meeting with + talking to lots of potential suppliers lately in order to have the best possible selection to offer clients.

Hopefully this post has explained a little more about what I do! If you're interested in working together, you're welcome get in touch by clicking here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

How is an on-trend print is created?

A lot of work goes into creating an on-trend, commercial + high quality print. This post goes behind the scenes to see how print are developed...

You may have seen my post a couple of weeks ago on how professional designers create a moodboard (if you missed it you can catch up by clicking here). In the post I covered how I create my moodboard, that I follow when creating fashion + print ranges. This post covers the next part of the process, designing the print.

As we discussed in the last post, I created the moodboard below, by combining information from trend reports that I have purchased, things that I have seen happening in industry, for example at trade shows + trend seminars + also my own style preferences. I touch base with the moodboard all the time, to ensure that I keep on track, I always have it open when I'm developing new ideas.

For this example, I'll use my Neon Palms moodboard shown below. When I start designing, I also refer to other inspiration that I collected along the way, that may not have been a good enough fit for the moodboard, but still of use. For example, close up shots of palm leaves, neon light usage, colour inspiration + in this case, research I did on tropical scenes + palm tress. This 'primary' research is always so important, as it ensures that my designs are completely original. Lots of designers follow other designers for ideas. I personally don't do this, as I think it limits your own creativity and can make you feel a bit 'blinkered' (like you can only think of what you've seen + get stuck in a rut) I find that using my own photography + references really helps my design process.

The images below were taken at a light installation in a park. These shots are perfect for the Neon Palm theme, there's lots of different types of palm leaves/trees for inspiration + the lighting reinforces the neon aspect of the theme. I used these to sketch + paint from - I often start with traditional arts techniques, again to get my own personal style into each piece I create. I used these palm leaf photos to develp my own motifs. For the particular design I'm showing you, I decided to do a silhouette of the leaves which were hand sketched and digitised.

Below shows some of the motifs I created from the palm tree photos. I kept referring back to my trend reports + I liked the concept of mixing stripes with palm leaves + as you can see started to experiment with that. Then came the colour - a bright mix of pink + green, which I mixed in a more modern way than the simple stripe with palms overlaid. I love this bright colour, but appreciate it's not for everyone, so I've also made this available in black + white, plus a trend led but slightly more subtle green + purple option. Interested in getting some print designs done? You can click here to chat about working together.

5 tips for selling print designs to buyers - feature on Print + Press London

I'm thrilled to be featured on the Print & Press blog this month! I've been talking Beki at Print & Press about successfully selling your print designs to a buyer...

I'm delighted to have been featured on the Print & Press blog this week! If you're not familiar with Print & Press, they offer digital printing services perfect for small businesses + they also run a blog with tons of helpful content on printing, selling your products + creative ideas. I've been featured on the website, as I'm sharing my best tips for print designers to get noticed by print buyers. I've been on both ends of the spectrum, a print buyer + a print designer + in the post I'll be exploring what print buyers are looking for. You can read the full post on the Print & Press blog, by clicking here. There's even a free checklist I've created to help you prepare for your next pitch!

I'd love to hear your thoughts on this, or any ideas you have for future blog posts. Feel free to leave a comment below, or send me a message here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

Client success; Griarté

It's lovely to be able to share with you a great brand, aimed at the sports + streetwear market. You can shop Griarté's new range, here....

It's always so rewarding to see things come together + become available in stores, not just with my own work + designs, but also clients that I've coached or worked with in some small way. A couple of weeks ago I was happy to hear from a client who I'd done some custom print designs for a few months earlier. The brief was to encorporate the company logo + create some placement prints suitable for the streetwear market. The brand, Griarté, combines activewear + streetwear influences to create a range of products that aims to encourage people to live more active + healthier lives.

As you may know, I'm passionate about giving back, in any way you can. One of the things I love about Griarté is their philosophy, they have a foundation which receives 10% of all of their profits. The Griarté foundation helps a variety of people, with a focus on child education + health. You can read more about their work + donate via their website - www.griartefoundation.org

It looks as though this style has now sold out, but you can shop similar styles by clicking here.

I wanted to share a few images from the brand, you can click on the images to shop. These are the first few prints I've created + there's more to follow - I'll keep you posted! I'm really excited to be able to share what Griarté has achieved so far. If you'd like to know what custom prints can do for your brand, feel free to get in touch here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

Packages tailored to small + startup fashion labels

If you're a small or start up fashion label, I'm now offering packages completely tailored to you, learn more about the options, which start at just £40, here.....

One of the most important things you have to do in business is to listen to your customers, not only at the start when you're finding your feet, but throughout the life of the business. I often take time to review what my customers have been saying + take action - whether it's a small or large change. Over the last month I've been working on 2 major changes, an update on my print design offering + also packages that are tailored to specific customer needs. You may remember that I did previously offer packages, but the feedback I was getting was that it was a bit confusing to find relevant packages. After delving deeper into the feedback, I found that some clients are confident with industry terminology, they've already had their own range + are looking to make it better, whereas others are excited to start a label, but haven't got any experience + haven't really started a business yet. So, I've now split my offering into groups that are relevant for your situation, which I'll go into a little more detail below;

The new 'work with me' page has been simplified, as above. You can choose to get in touch with me (I'm always happy to answer questions, so if you'd like you can contact me here + tell me a bit about yourself), or view all of the services available at once, but the easier way to find what you need is by selecting which statement applies to you. All of the packages are cheaper than buying individual services from me + are budget friendly. I know that funds are tight when starting a business, but it's important to get the help that you need + I want to make sure that it's accessible to anyone who has a vision of going out + starting their own label, so my offering starts at £40 (approx US$52 at the time of writing). Here's a little more information on each of the statements + how they can help;

I have an idea for starting a fashion label

This category applies to people who don't have experience within the fashion industry + want to learn the basics and/or people who have ideas, but haven't started producing any clothing yet. This section will explain things in more detail, so you don't have to worry about not understanding terminology. It's also clear about what you get with each package, you can choose from only designs or designs + technical documents, both of which include one-on-one coaching sessions with me so that you can get the most out of the experience + improve your understanding of the industry. The startup packages can be found via this link.

If you're new to the industry + would like a handy reference sheet with definitions of fashion industry terms, you can click here to learn about my free ebook with fashion industry terms.

I want to get my designs into production

This is a common problem that my clients face; they love designing + know what they want to make, but have no idea to start, what they need or how to get the best prices. These packages are specifically for these people, who haven't started production yet + would like some direction. There's options for tuning your designs into technical documents that a factory would understand, as well as coaching help to understand the process of production + working with a factory. A personal favourite of mine is the option to have your fashion range reviewed + assessed for potential problems, so that you can minimise the risk of going into production. This includes looking at your designs from the perspective of a customer, buyer, the press, pattern cutter, merchandiser, garment technician + factory to make your range the best it can be. You can view all of the packages tailored to this type of business, here.

I want to increase my profits + expand

If this is you then, congrats! You've already launched your fashion line + although you may not be seeing the profits that you'd like, you've made a start! This section is for those who have already had a range produced by a factory or seamstress + either didn't see the sales they wanted, or the product wasn't as well made as they'd have liked, or, they're happy with the way things are + want to expand. Expand can cover a range of things, it may be getting into stores + selling product in more places, adding a new type of product to the range, or providing items for a different type of customer. These packages cover more advanced strategies + cover things like getting the most profit for the best quality, improving your product offering based on sales + building a better relationship with suppliers. All of these packages come with consulting sessions to ensure that you fully understand the techniques + strategies we talk about + to give you the opportunity to ask specific questions relating to issues that you're having, areas that you want to improve, or business development ideas that you have. All of these packages can be viewed here.

Want to learn more about working together? Click here to get in touch.

How I create a tech pack for your fashion design

This post covers important decisions that are made on a tech pack, what to consider + why it's important...

If you've read my previous posts on tech packs, you'll know how essential they are + why it's so important for you to have them in your fashion range. If you've not seen those articles + aren't sure what a tech pack is exactly, you can read the posts here. This post covers decisions that are made in order to create the tech pack + why it's important for clients to provide as much information on their customer as possible.

A lot of clients come to me with only a design + don't have any preference on fabrics, trims + techniques, so I ask a few questions in order to establish what they are trying to achieve. This helps me to tailor the techniques + components to suit their brand. Of course, if client's come to me with their own ideas, I'm happy to work around those.

So what considerations are there?

What is the retail price range?

You're probably bored of hearing me say this, but I like to be realistic + treat fashion as a business. It's lovely just making what you want, but in the real world you're unlikely to last long with this approach. In fact, clients who don't treat their range as a business are more often than not the ones who's business experiences financial problems.

When I'm given a price range, I can then tailor fabrics, trims + techniques to suit this. For example, I'm not going to suggest silk for a range that retails at £30 as this will be out of budget. For expensive ranges, these need to have high quality finishes, such as neat seams without any raw edges visible (even inside), lining + beautiful fabrics - a cheaper range wouldn't be able to afford these. Another part of the tech pack that's affected by the price is the tolerance (the amount of different you're willing to accept between what you've requested + what the factory have made). If you're at a cheaper price point, + therefore cost price, the factory will be less likely to allow small tolerances. Whereas, expensive ranges will be paying a premium + therefore the tolerance will be minimal.

Who is the customer?

Again, something you've probably heard me say hundreds of times, but it's so important! For example, something key on the tech pack is the measurements. The factory will base the first sample on these measurements + of course the fit process will allow the client to perfect the fit over several sessions (related post; ultimate guide to fit sessions), but, the more information I have on the client to begin with, the better the first sample will be + the less changes you have to make. Let's take an example, if I know the customer prefers loose fit styles, I can create the measurements accordingly. If the customer is based in China, I know that statistically the measurements will be smaller than someone in the US, for example, + I can create the measurements relate to them. The measurements also control the styling, so it's good to know if your customers have any preference of sleeve length, how low the neckline is, etc + I can work accordingly. Although garment measurements aren't an exact science (you can learn more about the irregularities in sizing here), information on customer preferences helps to get the best possible results for your first fit sample.

What is the fabric?

As I mentioned earlier, I can make suggestions if the client hasn't selected a fabric already. I can suggest a fibre composition + finish as relevant + ask the factory to send options for the clients selection, so they can check the quality before purchasing the fabric. When making the tech pack, I consider the fabric type + how this will effect the techniques used. Most commonly, I look at stretch fabrics vs non-stretch fabrics, as the type of stitch used is very important + is different for both fabric types. On stretch fabrics, the stitches must be compatible with the stretch, otherwise the stitches will rip + a hole will be created.

What is the size range?

If the size range is small, for example size small, medium + large, usually there's only a need for one set of grade rules is required (the amount of difference between each size at each point of measure - you can download a quick reference glossary of terms below if you'd like). However, for a larger size range, perhaps size 6-18, 2 sets of grade rules would usually work best. Therefore, it's good for clients to make a decision upfront on what sizes they will be making, so the grade rules can be written accordingly.

Hopefully this post has helped you to understand more about what goes into a tech pack + how I tailor my service specifically to you. If you'd like to learn more about how I can help you, you can either view my list of services by clicking here, or get in touch via this link for more information..

There's lots more free fashion industry information coming up on the blog, including mistakes to avoid when you're starting a fashion label + the first steps to take when starting a new business. I welcome suggestions for future blog posts, so please feel free to ask for a particular topic in the comments below....

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

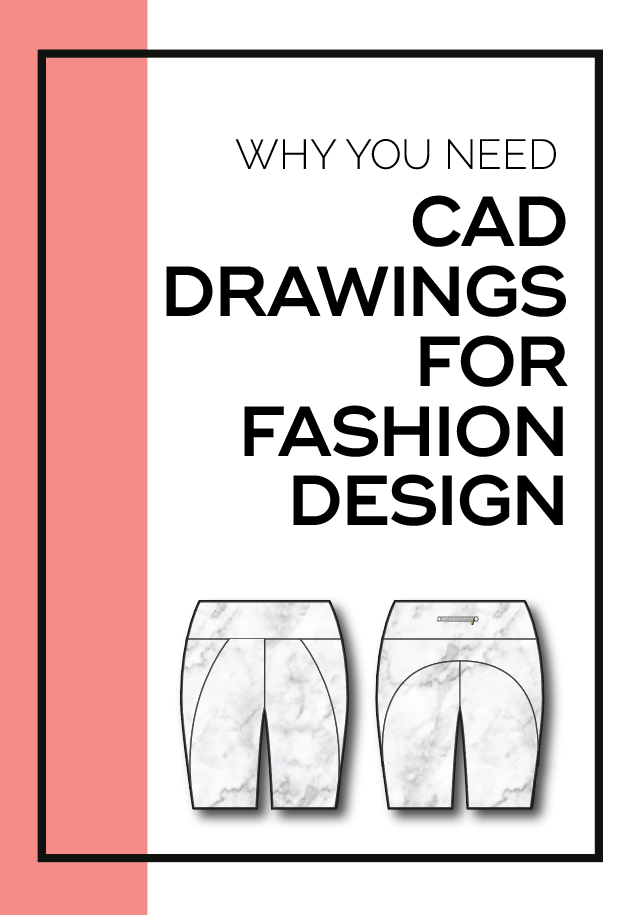

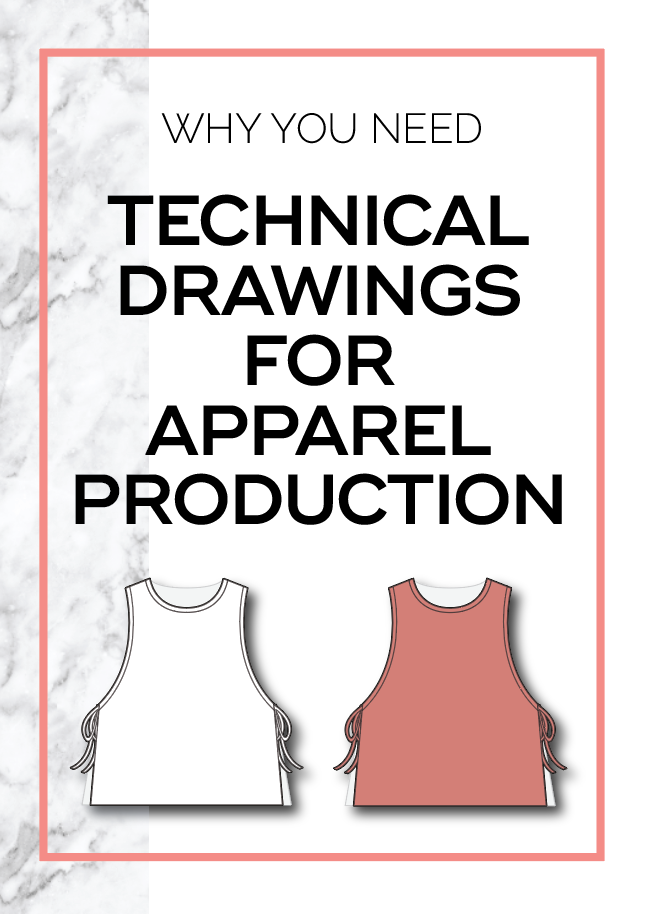

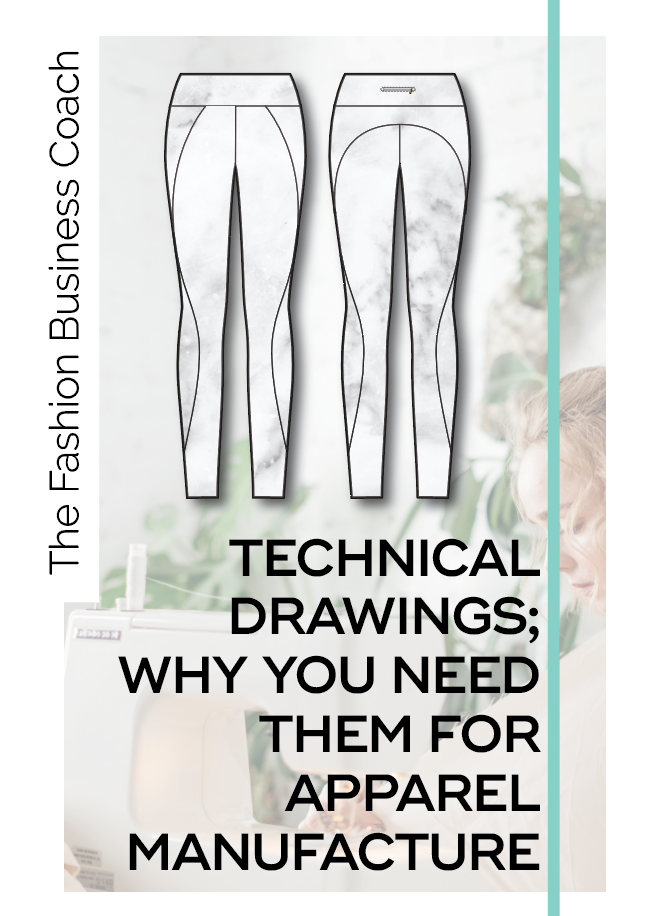

What is a technical drawing and why do you need one for apparel production?

This post explores what a technical drawing CAD is, the work that goes into it + why you need one to get your fashion designs made

What is a technical drawing?

First and foremost, what is a technical drawing, or CAD (computer aided design), as it's sometimes known? A technical drawing is the fashion industry equivalent to a blueprint, it shows the factory or pattern cutter the shape of the garment when laid flat, without any artistic flare or stylisation. It clearly shows the details of the garment, including things like stitch type, shaping such as darts or tucks, trims and fastenings. Most of the time, only a front and back drawing is required, but on some occasions an internal and/or side view might be needed. For example, a ski jacket would often need an inside view to show the position of internal pockets.

Need technical drawings for your fashion range? Click here to learn about how you can get them for your collection.

Why isn't a photo or sketch of the garment enough?

The first issue here is that they often show the garments on a model. While this can look very nice, this isn't very useful for production, as models are usually drawn disproportionately to a real human figure. This can cause confusion over what the actual proportions of the garment should be and can distort the width vs height ratio of the garment. AKA, your clothes won’t fit your customer well. The second reason is that the detail needs to be really clear, showing every seam, stitch, dart, rivet, etc and a sketch or photo can't offer this level of detail. The technical drawing is 'flat' which is also key as the factory will measure a flat garment to make sure the proportion is correct, so it makes sense that the drawing is the same as what the factory is looking at.

The technical drawing, in conjunction with the tech pack act as an 'instruction manual' for the factory, so they can make samples and quote a price to you. If you're not familiar with a tech pack, you can read more information in this article.

Here’s an example of some of my technical drawings.

2 Versions of the drawings is helpful

Ideally, there should be 2 versions of the technical drawing, a black and white version and a colour version. The colour version is great to refer to if you have a garment with more than one colour within it, so the factory can easily see which part of the garment is in which colour. This makes production easier for them and minimises confusion. The black and white version is also important, as it makes it really easy to see the stitches and details without the distraction of colour (especially if the colour is dark as it makes it really difficult to see the detail!). The black and white one is used in conjunction with the measurements in the tech pack. Arrows will be placed over the black and white drawing to show the factory exactly where they should measure. For this reason, I include a black and white version, plus colour versions in my tech packs as standard.

Here’s an example of some of my technical drawings in colour.

More than just a drawing

Is the technical drawing basically copying a sketch or photo into a CAD (computer aided design) drawing? Partly, yes, but a lot more goes into it than that. The CAD drawings may seem simple at a glance, but every detail has be be considered and importantly, the construction. For example, how will the edge be finished? Will it be left raw, single needle stitched, cover stitched, bound, faced, lined? Each opening (hem, neckline, cutout, etc) has to be considered and a technique relevant to the style and fabric has to be carefully selected. So while the drawings themselves may appear fairly simple, on the small example range above, options have been considered and decisions made for 39 edges! And that’s only the edges, not thinking about things like fastenings and other trims too!

You'll notice that there's some variation on the types of finish that has been used. This is a simple example, but many other things are considered, such as how you'll get into the garment, does it need a zip, are darts needed for shaping, will the seams work well or does it get too bulky, etc. A technical drawing is much more than a digital drawing and needs to be created by someone with a lot of garment making experience, rather than just someone who knows how to draw digitally.

I hope this post has given you an insight into the amount of work that goes into each and every technical drawing. As always, you're welcome to leave questions in the comment box below and I'll be able to answer them for you.

If you're interested in moving forward with your range and taking the first step towards having your designs made, I’d love to help you! You can learn more about my idea to factory ready service by clicking here, or you’re welcome to contact me here.

What goes in to my fashion design service?

Think a design service is someone drawing pretty pictures? Think again! This post covers the many things that go into a design, from financial considerations, to trends and manufacturing...

On the surface of it, you might just think 'oh, design service. Someone will design pretty clothes for me'. I wish it was that simple! The scary thing is that this is a common misconception about the fashion industry, even from designers who haven't worked in the 'real' side of fashion. It is a business and as such, absolutely everything you do has to be business focused. It would be lovely to just design whatever you'd like, but the reality is that each item must sell for a good profit, otherwise you'll find yourself bankrupt in little to no time. Even the multi-millionaire daughter of a Beetle, Stella McCartney, has to design around a business focus in order to sustain a brand.

I've been fortunate enough to work in lots of different areas of the fashion industry and this has led me to work in a different way to many others, because I foresee the production problems while still in the design stage. If you've never been a pattern cutter, sample maker, or production manager and have always stayed in design, it's easy to keep passing your designs on, blissfully unaware of the nightmare that you're causing the factory. So when I'm designing a range for you, what do I take into consideration?

1. Who am I designing for?

This is where you, as a client, can be very helpful. The more information you provide on your target customer and the type of brand you're trying to create, the more I can tailor the designs to you. I provide a designer briefing sheet to help you get your ideas and customer across, be as detailed as you can with this. I'm sorry if it feels like I'm giving you homework, but it's for the best, I promise! Let's take an example. A customer approached me to design a new swimwear line and sent some examples of string bikini styles they liked, but didn't want to tell me anything about their customer. So I took inspiration from the string bikini. They later told me that the range would be available in plus size cups.....had I known that before, I would have told them why a string bikini isn't a good idea for this market and would have designed accordingly. I wouldn't have expected them to know this, 'you don't know what you don't know', but if they had been open about they're customer I could've created better designs, suitable for them in particular.

You might feel that some of the questions on the sheet are a bit useless, but in all honesty I developed that sheet after years of experience and can assure you that each question is totally valuable, so the more you can tell me, the more I can work for you specifically.

2. What is the price range

One of the questions you might find odd is 'retail price range', you might be thinking 'well, the price will depend on the price I get from the factory'. Please never think this and don't allow the factory to dictate your retail prices! I'll be covering this topic in more depth in an upcoming blog post. You, or your market research should determine the retail price. For example, if you'd like me to design a range to sell for £10-£50, the fabrics and techniques I choose will be very different to one that sells for £70-£300. To the client, it may look as though the price doesn't really affect the deigns, but this isn't the case at all. Subtle variations, such as construction and fabrics can make a huge difference to the price, all of which are considered when I design. I like to present designs to clients that are commercially viable and it's no help to anyone if I present 100% silk styles to someone who wants to sell for £30 - they will never be able to get this into price.

3. How will this be manufactured?

Each design I submit has been considered from a pattern cutter, sample maker and factory perspective, even if you're not getting any technical services from me. I see so many designers submitting work, which ends up coming to me for correcting, as the designer hasn't considered how to make it and later realise it's not actually possible. Let's take a simple example, a customer came to me recently for a consulting session. Someone had done designs for her, but the factory we're really struggling to understand what they were making. The answer was simple; the designs didn't have a back view, an individual view (coats were covering the tops, so you didn't know if they were long sleeve, short sleeve, etc) and as they were presented as fashion illustrations, they were disproportionate. I love fashion illustrations and think they could be a great addition to branding, marketing, social media accounts, etc. However, in the manufacturing world they are very confusing. Fashion illustrations are usually disproportionate and are essentially 'stretched out' about 20%, so the legs and torso are much longer than on a real body. This makes it hard for anyone trying to produce the garment to identify the true proportion. That's why I always present my work as 'flat' CAD drawings that are easy to understand and provide a front and back drawing as standard. I appreciate this doesn't look as exciting as a fashion illustration, but you have to ask yourself if you want exciting, or if you want to actually get a finished piece of clothing.

I also consider things further down the track, into pattern cutting and production. This is something that you won't see in the designs, as basically I won't send anything to you that'll be really hard or impossible to produce. This makes it easier for clients, as they don't have to consider their factory, they can just make selections based on personal preference.

4. When is the range for?

Another question I ask is, when are you launching the product. This is both so that I can take into account any trends and also so that I can choose suitable fabrics and make sure the collection is seasonally appropriate. Something important to note about trends; I don't believe in being a slave to them and the use of trends will come back to the target customer. I believe there's a big difference between 'trend led' and 'trend relevant'. For example, if I'm designing for a fast fashion company appealing to 16-25 year olds, trends will play a key part in the design process. If, however, the range is evening wear for the over 50's, trends will still be considered, but they won't be the driving force. In most cases, unless the client requests differently of course, this type of design would be something I call 'trend relevant', meaning the designs fit in with the season's styles, but also have a timeless quality and won't date quickly.

5. How will this work together as a range?

'Range building' is one of the most important things to get right, in order to increase the company ATV (average transaction value), UPT (units per transaction) and generally lead to greater profits in the business. By making sure that the collection works together as a range and is interchangeable, you can encourage customers to make additional purchases. For example, they might be looking for a top, but could end up adding the trousers and/or jacket to complete the look. Or, they might buy the kaftan that compliments the bikini set. The other thing to consider when designing a range, is how many of each category (e.g; top, bottom, dress, etc) and also the price (again!) structure. I look into sales data for various market sectors and will use the one relevant to the target audience I'm working with to decide on both the breakdown of categories and also how many items are low, medium and high priced (whatever those prices may be according to the client's retail price range). This can all get a bit overwhelming (sorry if I lost you at ATV), but essentially, I can worry about this so you don't have to.

6. How will this be perceived by the press and buyers?

Another thing to consider is how the collection will look to professionals. Of course, the range will be customer focused, but in order to get the product in front of customers, it needs to get some publicity. This is also a reason to keep the range trend-relevant, even if you're not interested in being trend focused, as magazine editors and bloggers will be working to a specific theme. Press are also inclined to seek 'special' pieces, known to designers as the 'press piece'. The press piece isn't usually the bestseller, but it gives the brand exposure and publicity and is a style that customers aspire to own; more on this topic in a future blog post. Buyers will of course consider price, but also how the clothes work together and how they can be merchandised (displayed together for maximum impact and profitability) in store. I, therefore, also consider these things in order to produce a fashion range that can appeal to press and buyers, as well as your customer.

I wanted to clarify that all of the above is included as standard with any designs that I create. Essentially, you're getting advice as I'm considering all of these things for you, but we're not necessarily having a discussion about it. This allows you to choose designs in confidence, based on your personal preferences without having to consider all of the above. If you want to make some changes but not sure if they'll work, I'm more than happy to tell you if they're suitable and achievable.

I hope this post has given you some insight into all of the decisions and considerations that go into each and every design I create. If you'd like to ask any questions, you can send me a message here. There’s also a full list of the services I provide, which you can view by clicking here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

How to use and complete a tech pack for your fashion design

Demystifying the tech pack; what the terminology means and how to fill the sheet in.

Last week, I wrote a post on tech packs - why you need them and what they include (you can read that here if you missed it). I mentioned that the tech pack is a working document that needs to be edited and updated over time. This can be quite daunting for people new to the industry, especially those who think they can hire someone to make a tech pack and that's it, there's nothing more to be done. This post goes through the information in the tech pack in it's earliest form, what it means and how it can affect you.

For this post I've used a basic examples of spec sheets I've created. Of course, different garment technologists will have a different approach, but this is the basic template that I use for spec sheets I create for my freelance clients. Even if the formatting is different in other tech packs, the overall content and the key things to look out for will remain the same. You'll notice that in each box I've written some suggestions. I tailor this for each of my clients to give them a guide, so please be aware that the information on this spec sheet may not be relevant to your situation. I'll go into more detail on this in a moment.

Here’s what should be included in your tech packs;

Colour, pretty obvious but do be sure to update it if the colour changes

Fabrics, these may start off as fabric ideas and the fabric will be confirmed at a later date (more on that in this post). When the fabric is finalised, be sure to add the composition and weight, plus any codes or reference numbers

Delivery date - be clear what you mean here - delivery date to you, the port, the airline? Be specific about where the stock should be delivered and when

Trim and label information - when the fabric is confirmed a care label can be created. You'll need to specify where you want this and any other brand/size labels. You'll also need to specify which labels to use and who will be providing them

Samples required - the more samples you can get the better, but of course the factory will only agree to so many. I like to have a good sample of sizes so I can check the fit across the size break, but this isn't always possible depending on what you've agreed with the factory. After you've discussed how many samples you can have, you can enter your size requirements here. The size you ask for will depend on your brands customers, your fit model and your advertising model, if you have one.

Lead time - how quickly you expect the factory to send the next fit sample, after they've received your spec sheet (in the first instance) or fit comments. The length of time will previously have been agreed with the supplier in your contract or service agreement, but it's good to put it here as well so the person working on the development is aware and there's no excuses for it being late.

Packing information - these requirements will often be set by your distribution centre, or you if you will be the one sending out orders to customers or stores. For example, some companies are not set up to receive hanging stock, everything has to be flat packed. Some will even specify the maximum size of the package.

Fabric testing - if you wish to carry out any performance tests on the fabric, you can note these down here.

Packaging information for the cartons - this information will come from your freight forwarder (or courier service for small scale businesses) and your distribution centre. Different companies will have different information that needs to be on the box, you only have to fill in the information required and the factory will enter the rest, for example, how many items are in the box, the weight, etc.

REF refers to the letters on the diagram

Measurements shows the point of measure. You may amend this as you go through the fit process, if you add or remove elements.

Original measurements will be for your chosen fit sample size and the first fit sample will be made to these specifications.

1st fit, 2nd fit, PP, etc - in this column you write the measurements of the garment that you receive from the factory

+/- in this column you write the difference in the measurements between what you've asked for and what the sample actually measures

1st amended spec/2nd amended spec - after fitting the item, you will use this column to request changes to the next sample. There can be a lot of changes throughout the fit process, so this is really important. It's impossible to get a great fit the first time, because it's hard to predict how the fabric and components will react (especially as the spec is usually done before the fabric is confirmed). Things like the weight of the fabric and amount of stretch can make the fit dramatically different, so make sure each sample is sent to you in the correct fabric.

Final spec - when you're happy with the way the garment looks, enter the measurements of that garment in here. The factory will use this to make bulk.

Shipping sample - the factory will send this for your final approval before shipping the stock

Grade rules - these will alter depending on your customer and market. Grade rules dictate the difference between each size. If you're able to get extra samples made up by the factory so you can check that the style works in each size, that is preferable. If not, try to look at your market research and see any patterns in your customers measurements, particularly those who wear the same dress size. You could also ask the factory for information on products they've done for other customers in the same market.

Tolerance - this is the maximum amount of difference that you are willing to accept between what you have asked for and what you receive. For example, if the measurement should be 40cm and the tolerance is 1cm, you may receive a garment that is 39cm or 41cm. This can alter the cost price a lot and generally the numbers here will be smaller for high end ranges and higher for budget garments. Tolerance is often something that is discussed at the contract stage with the factory as it's good to outline your expectations from the start.

Construction comments - these may need to change depending on the factories capabilities and the equipment they have. They might also have to change if the cost price is coming out too expensive and you need to use cheaper methods. Often components such as zips and buttons will be included here and will need sourcing, when the component is confirmed the specifics will have to be noted here.

Not everyone will require page 3 as this is for any placement prints or embellishments, if the print or beading is on the fabric, this will fall under page 1. Page 3 has the specifics of the technique needed and the measurements of the placement. The information on this page is quite straightforward and will just need to be updated if the print size changes and the print method will need to be added here when confirmed.

Extra pages

Sometimes there will be a need for additional pages, depending on the design and also the requirements of the company. Some may ask for an inspection of bulk, so a page will be created for the factory to write down their findings. Some people prefer to add an extra page for fit comments and space for photos. There can be variances but these are the key details to look out for.

If you're planning on producing a fashion range + need help with tech packs, you can learn more about the service I provide and how it can help you, by getting in touch here. My tech pack format is tried + tested + has been used to get hundreds of products into production, for both startup and established brands. Alternatively, you can see all of the services I provide, here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

New services; the complete package for new fashion lines, with consulting help

New services available for startups and small businesses who need help with their new fashion range....

I recently read an amazing article on the Business of Fashion website (a great resource and I'd highly recommend subscribing to their mailing list if you want to know whats going on in the industry) about launching a fashion label, which you can read here. It made some excellent points about the traps that many people fall into. It's so easy to get carried away with ideas and rush into things, but the reality is that a fashion brand is a business, people can't be successful on ideas alone. “To be honest, I don’t know how (other) young brands can start without any business experience,” says Laura Kim, at Oscar de la Renta and I agree - dealing with factories, technical specifications and shipping profiles can be exhausting and a real drain on your creativity. Another quote I found spot on was “The time of self taught maestros has come and gone,” says Luca Solca, head of luxury goods at Exane BNP Pariba. This article has spurred me on more than ever to try and help small and startup labels to get some helpful insight into the very secretive fashion industry.

Who are the new packages for?

My new packages are aimed at those who would love to have their own fashion line but aren't sure where to start, or perhaps they lack experience in the technical side of fashion. I do still offer one off consulting sessions, but the packages I’ve developed have been carefully curated to give a better overall result. The packages all include one-on-one time with me, so we can really look in detail at your situation and identify problems early, so they can be avoided - you're essentially learning from my mistakes! I'd love to say I purposely made all those mistakes with my first business as a cautionary and educational tale for you - but sadly no, I was just young, excited and inexperienced! The packages are completely tailored to your situation, so it doesn’t matter what stage you’re at, or what you’re struggling with specifically, we can create something that works for you. For more information on how I can help, click here. Alternatively, you can send me a message via this link.

Who are you?

If you're new to this website you're probably wondering, who is this person and why does she think she can teach me stuff? Sorry; I'm Vicki, founder of 29andSeptember Studio. I've got 12 years experience in the fashion design and production business and have worked on ranges from their initial idea right through production, merchandising and selling in store. Now I help a range of clients realise their dream of owning their own fashion label by educating them on the ins and outs of the fashion industry. You can learn about my story here if you'd like. On the less formal side, I love to create, decorate my house, eat Ben and Jerry's and drink lots of tea (English tea, like me).

What do I get in the packages?

I now have 4 packages all carefully designed to help with a specific need. As I mentioned, each package includes mentoring time, which can be used to address the issues you're most worried about, or the area of the business your struggling with. I can even look at emails and documents from suppliers if you'd like and we can go through them together;

Range review; I can go over the designs you have created and identify potential problems, both with production and also selling the product to customers

Monthly coaching package; this service allows you to have regular coaching sessions so we can review your business, progress you've made and set targets for the future. It'll also help with action steps to get you closer to your goals.

Complete production package; if you've finalised your designs are are ready to get them made, this service will provide all the tech packs and documents you need to get your samples made. It also includes education on the production process and tips for a successful end product

Complete design + production package; this includes a custom designed range perfect for your customer and style, plus tech packs and help with approaching factories and getting the deigns made.

This gives a really brief overview of each package, as always you're welcome to ask me any questions, or you can read more about ways of working together, here.

I'd love to hear what you're working on at the moment, or what your current aspirations are - if you're happy to share there's a comment box below...

Thanks for reading!

What is a tech pack and why you need one for apparel production

This post explains what a tech pack includes, why it is useful and why you need one for your fashion business.