How I create a tech pack for your fashion design

This post covers important decisions that are made on a tech pack, what to consider + why it's important...

If you've read my previous posts on tech packs, you'll know how essential they are + why it's so important for you to have them in your fashion range. If you've not seen those articles + aren't sure what a tech pack is exactly, you can read the posts here. This post covers decisions that are made in order to create the tech pack + why it's important for clients to provide as much information on their customer as possible.

A lot of clients come to me with only a design + don't have any preference on fabrics, trims + techniques, so I ask a few questions in order to establish what they are trying to achieve. This helps me to tailor the techniques + components to suit their brand. Of course, if client's come to me with their own ideas, I'm happy to work around those.

So what considerations are there?

What is the retail price range?

You're probably bored of hearing me say this, but I like to be realistic + treat fashion as a business. It's lovely just making what you want, but in the real world you're unlikely to last long with this approach. In fact, clients who don't treat their range as a business are more often than not the ones who's business experiences financial problems.

When I'm given a price range, I can then tailor fabrics, trims + techniques to suit this. For example, I'm not going to suggest silk for a range that retails at £30 as this will be out of budget. For expensive ranges, these need to have high quality finishes, such as neat seams without any raw edges visible (even inside), lining + beautiful fabrics - a cheaper range wouldn't be able to afford these. Another part of the tech pack that's affected by the price is the tolerance (the amount of different you're willing to accept between what you've requested + what the factory have made). If you're at a cheaper price point, + therefore cost price, the factory will be less likely to allow small tolerances. Whereas, expensive ranges will be paying a premium + therefore the tolerance will be minimal.

Who is the customer?

Again, something you've probably heard me say hundreds of times, but it's so important! For example, something key on the tech pack is the measurements. The factory will base the first sample on these measurements + of course the fit process will allow the client to perfect the fit over several sessions (related post; ultimate guide to fit sessions), but, the more information I have on the client to begin with, the better the first sample will be + the less changes you have to make. Let's take an example, if I know the customer prefers loose fit styles, I can create the measurements accordingly. If the customer is based in China, I know that statistically the measurements will be smaller than someone in the US, for example, + I can create the measurements relate to them. The measurements also control the styling, so it's good to know if your customers have any preference of sleeve length, how low the neckline is, etc + I can work accordingly. Although garment measurements aren't an exact science (you can learn more about the irregularities in sizing here), information on customer preferences helps to get the best possible results for your first fit sample.

What is the fabric?

As I mentioned earlier, I can make suggestions if the client hasn't selected a fabric already. I can suggest a fibre composition + finish as relevant + ask the factory to send options for the clients selection, so they can check the quality before purchasing the fabric. When making the tech pack, I consider the fabric type + how this will effect the techniques used. Most commonly, I look at stretch fabrics vs non-stretch fabrics, as the type of stitch used is very important + is different for both fabric types. On stretch fabrics, the stitches must be compatible with the stretch, otherwise the stitches will rip + a hole will be created.

What is the size range?

If the size range is small, for example size small, medium + large, usually there's only a need for one set of grade rules is required (the amount of difference between each size at each point of measure - you can download a quick reference glossary of terms below if you'd like). However, for a larger size range, perhaps size 6-18, 2 sets of grade rules would usually work best. Therefore, it's good for clients to make a decision upfront on what sizes they will be making, so the grade rules can be written accordingly.

Hopefully this post has helped you to understand more about what goes into a tech pack + how I tailor my service specifically to you. If you'd like to learn more about how I can help you, you can either view my list of services by clicking here, or get in touch via this link for more information..

There's lots more free fashion industry information coming up on the blog, including mistakes to avoid when you're starting a fashion label + the first steps to take when starting a new business. I welcome suggestions for future blog posts, so please feel free to ask for a particular topic in the comments below....

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

How many items should I have in my fashion range?

One of the most common questions I'm asked is 'how many items should be in my fashion range'. This blog post covers the things to consider when making this decision.

How many items should I have in my fashion range?

One of the most common questions I get asked is 'how many items should I have in my fashion range, how many styles + how many units? They often expect some sort of 'standard' or formula they can follow + unfortunately this isn't the case. I could just pick a number that I've seen other people use with success, but in order to really answer this question, the client needs to have a good understanding of their business plan + what they want to achieve. If you've read the blog before, you've probably heard me talk a lot about having a target customer + tailoring your offering to them. This also applies to choosing how many items to have. When deciding on the size of the range, there's a few things to consider. There's a few more advanced techniques in this post, if you're unfamiliar with some of the terminology you are welcome to register free for my Ebook 100 Must Know Fashion Terms. Click here for that.

Consideration #1 What products are you making?

For example, a company who only makes dresses will have a completely different strategy + needs to someone who makes a workwear range. On average, the dress company will start out smaller, as they only have one product category + and can launch with a few styles + test different fits/shapes with their customer. The workwear company will most likely need more styles as they have a wider range of products, dresses, skirts, tops, jackets, trousers, etc. There are more considerations, such as the ratio of the tops vs bottoms (in terms of sales this is very rarely 1:1), how the items are worn together + ensuring there are enough outfit options if you're wanting to do a photoshoot. In terms of having variety to offer customers, this could make the range larger as you test different lengths, for example.

Increasing your brands profits

One of the most successful methods of increasing your company profits is to increase the ATV. What does this mean exactly? Well, the ATV is a way of showing how much on average your customers are spending with you. Generally speaking, it's easier to convert one sale into 2, rather than having to find 2 separate people to buy something. Enter the 'add on sale', a key part of retail strategy. You want to make your range have complimentary items, so that a customer walks out with 2 or 3 items, instead of 1. For example, if you're starting a swimwear label, you might want to introduce a cover up, so that when someone comes in to buy a bikini, they also buy the cover up, thus increasing your ATV + profits. In terms of this relating to the size of the range, it may mean that you add some extra items into your original plan, to ensure there are some 'add on products'.

What is your budget?

I don't like to limit people's ideas too much with budgets, as I know it's possible to have a successful business with only a small initial investment. I started my own successful business with just a £150 investment (approx US$190 - you can learn how I did it in this post if you’re interested), so I don't like to prohibit people from doing things based on their wealth. If you are on a budget, of course there is a need to be cautious + order less initially. I'd still suggest trying a few different designs, but only ordering a minimal amount of each style.

What is the marketing strategy?

You might wonder what this has to do with the size of your range. Let's look at it this way.....if your business plan outlines a huge marketing campaign with lots of advertising, PR + influencer marketing, you will need enough stock to make sure you don't sell out. There's nothing worse than paying to promote a product that you don't have in stock. On the flip side, if you're going to keep costs to a minimum + concentrate on social media marketing, this will require much smaller levels of stock, as it takes time to build a following.

Another thing to consider is that if you want to do a fashion show, or photoshoot, it's in your best interest to have a lot of items, particularly for the catwalk show. Photoshoots + shows are very expensive when done properly, so you want to make sure you have enough product to showcase to make it worthwhile. For example, it'll be a very short fashion show if you only have 10 items + you'll have to sell a huge amount in order to recoup the thousands that you've spent on putting the show together. The other thing to consider is outfits, both of these options require full outfits to be worn, so you need to ensure there's enough options of bottoms vs tops to make this work.

How many sizes are you making?

You might have seen my post a couple of months ago about choosing a size range + the importance of identifying the best size break for your customers (if you've not seen the post you can read it here). The size range you're making also dictates the number of units to order, to an extent. You need to consider all of the sizes you're making + ensure that you've ordered enough stock for each item to be sent to each of your sales outlets, in every size. For example, online, stockists + stores. If you're only making 3 sizes, the minimum number of units you can order is much less than someone who is making 8 different sizes.

How many places will you be selling the range?

As with the point above about the number of sizes you're making, the number of places your stock is being sent to is also a factor in the number of units you order. For example, if you have wholesale orders, an online website + physical shop, you will need to split all of your stock between these outlets. You'll therefore need a lot more stock than someone who is only selling on their website. Do keep in mind that if you're selling on multiple outlets online, for example your own website, Not On The High St, Etsy, Amazon, you will need separate stock allocation for each of these sites + will need to order more than someone who only has their own website. A common mistake I see is people just allocating stock for 'online' + listing the same item on multiple sites, without having the stock to cover all of the sites. If customers order the same item on 4 different sites, you'll have to let some of them down, which is never a good thing.

At the end of the day, you have to decide what size range is best for you, but I hope this post has given you some things to consider + helped you to make a decision. If you're still unsure of how this applies to your business + would like some one-on-one help, my most popular coaching service is now available to book instantly online. This gives you a personalised consulting session with me on the phone, plus a summary email with all of the points we've covered + links to relevant resources if appropriate. If you're interested you can learn more by clicking here.

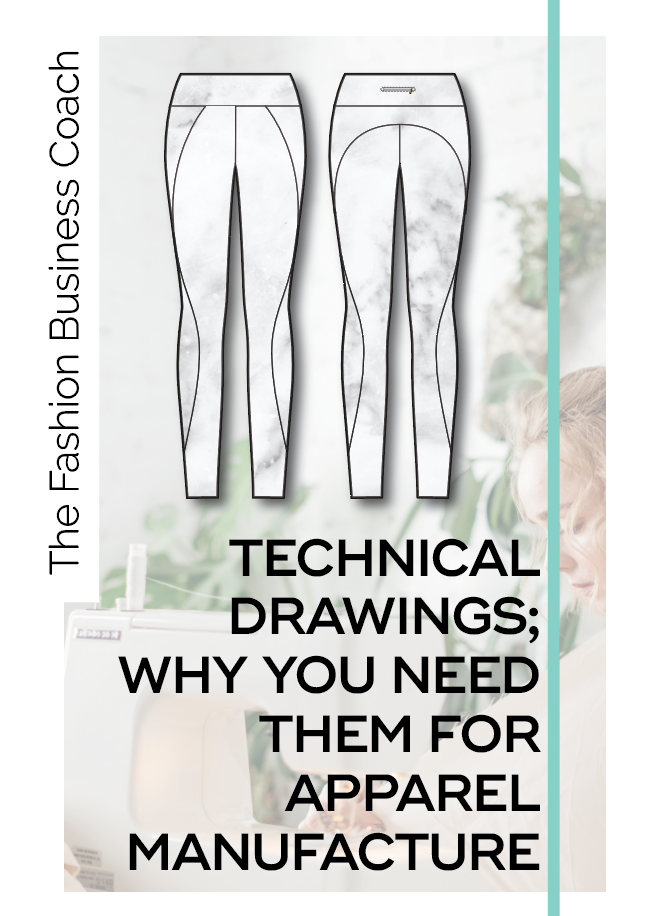

What is a technical drawing and why do you need one for apparel production?

This post explores what a technical drawing CAD is, the work that goes into it + why you need one to get your fashion designs made

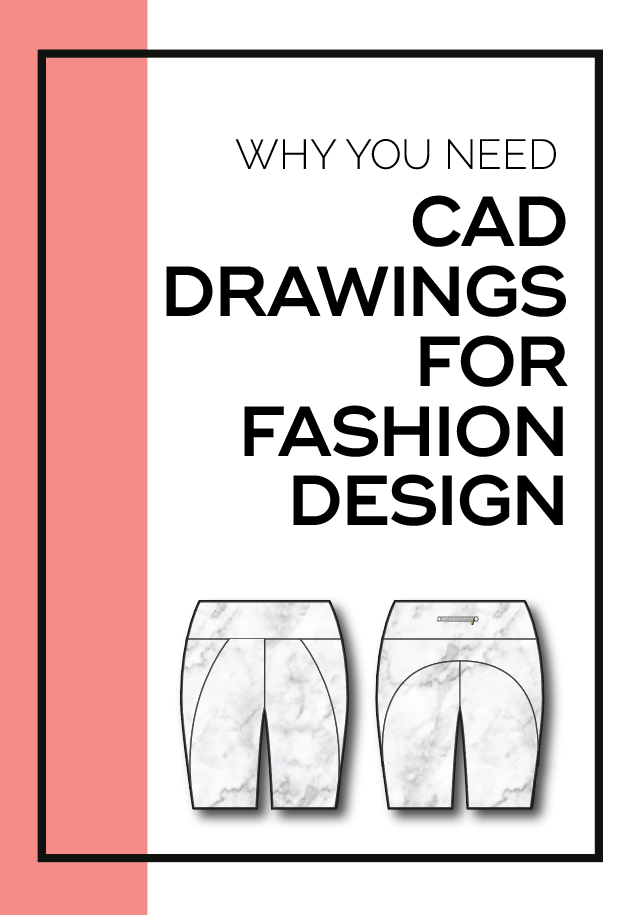

What is a technical drawing?

First and foremost, what is a technical drawing, or CAD (computer aided design), as it's sometimes known? A technical drawing is the fashion industry equivalent to a blueprint, it shows the factory or pattern cutter the shape of the garment when laid flat, without any artistic flare or stylisation. It clearly shows the details of the garment, including things like stitch type, shaping such as darts or tucks, trims and fastenings. Most of the time, only a front and back drawing is required, but on some occasions an internal and/or side view might be needed. For example, a ski jacket would often need an inside view to show the position of internal pockets.

Need technical drawings for your fashion range? Click here to learn about how you can get them for your collection.

Why isn't a photo or sketch of the garment enough?

The first issue here is that they often show the garments on a model. While this can look very nice, this isn't very useful for production, as models are usually drawn disproportionately to a real human figure. This can cause confusion over what the actual proportions of the garment should be and can distort the width vs height ratio of the garment. AKA, your clothes won’t fit your customer well. The second reason is that the detail needs to be really clear, showing every seam, stitch, dart, rivet, etc and a sketch or photo can't offer this level of detail. The technical drawing is 'flat' which is also key as the factory will measure a flat garment to make sure the proportion is correct, so it makes sense that the drawing is the same as what the factory is looking at.

The technical drawing, in conjunction with the tech pack act as an 'instruction manual' for the factory, so they can make samples and quote a price to you. If you're not familiar with a tech pack, you can read more information in this article.

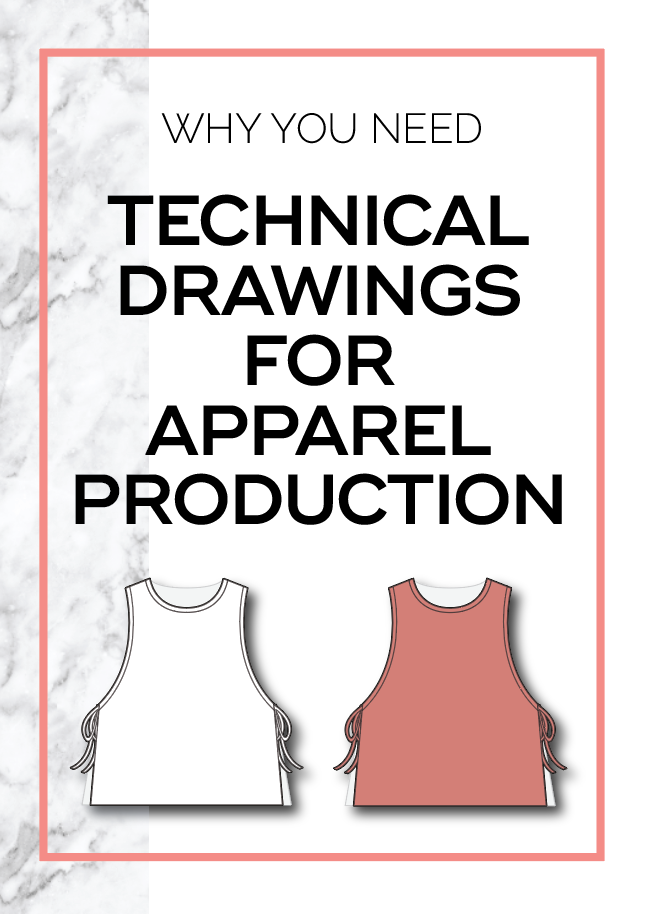

Here’s an example of some of my technical drawings.

2 Versions of the drawings is helpful

Ideally, there should be 2 versions of the technical drawing, a black and white version and a colour version. The colour version is great to refer to if you have a garment with more than one colour within it, so the factory can easily see which part of the garment is in which colour. This makes production easier for them and minimises confusion. The black and white version is also important, as it makes it really easy to see the stitches and details without the distraction of colour (especially if the colour is dark as it makes it really difficult to see the detail!). The black and white one is used in conjunction with the measurements in the tech pack. Arrows will be placed over the black and white drawing to show the factory exactly where they should measure. For this reason, I include a black and white version, plus colour versions in my tech packs as standard.

Here’s an example of some of my technical drawings in colour.

More than just a drawing

Is the technical drawing basically copying a sketch or photo into a CAD (computer aided design) drawing? Partly, yes, but a lot more goes into it than that. The CAD drawings may seem simple at a glance, but every detail has be be considered and importantly, the construction. For example, how will the edge be finished? Will it be left raw, single needle stitched, cover stitched, bound, faced, lined? Each opening (hem, neckline, cutout, etc) has to be considered and a technique relevant to the style and fabric has to be carefully selected. So while the drawings themselves may appear fairly simple, on the small example range above, options have been considered and decisions made for 39 edges! And that’s only the edges, not thinking about things like fastenings and other trims too!

You'll notice that there's some variation on the types of finish that has been used. This is a simple example, but many other things are considered, such as how you'll get into the garment, does it need a zip, are darts needed for shaping, will the seams work well or does it get too bulky, etc. A technical drawing is much more than a digital drawing and needs to be created by someone with a lot of garment making experience, rather than just someone who knows how to draw digitally.

I hope this post has given you an insight into the amount of work that goes into each and every technical drawing. As always, you're welcome to leave questions in the comment box below and I'll be able to answer them for you.

If you're interested in moving forward with your range and taking the first step towards having your designs made, I’d love to help you! You can learn more about my idea to factory ready service by clicking here, or you’re welcome to contact me here.

The harsh truth about the fashion industry, is it right for you?

So many people want to be in the fashion industry. But do you know what you're letting yourself in for? This post explores common misconceptions in the industry.....

A lot of people come to me for my coaching services + are looking for help in realising their fashion 'dream'. This usually involves designing clothes they love, promoting them with glossy photos on Instagram + becoming fashion world famous, which to a lot of people involves lots of shopping, front row seats at fashion week + parties. I hate to burst people's bubble, but at the same time I'm a realist + people come to me for my insight, so in the best interests of the client, I often have a bit of a reality check with them. In this post, I'm going to explore some of the common misconceptions of the fashion industry, some of the lesser know + 'unglamorous' sides of the business + also help you try + figure out if it's for you. Each role in the industry comes with different pro's + con's + I'll cover each of these in a future post. For now, let's look at the industry as a whole…

If after reading this you decide the fashion industry is for you, I’d love to help you launch your brand inside The Fashion Startup Online Course and Accelerator.

Misconception number 1; Fashion professionals go to lots of fashion shows

Let's think about this one logically. If you have a fashion brand, would you invite your competitors to your show, so they can see what you're doing? Of course not! As a fashion designer or business owner, it's very unlikely you'll be going to any fashion shows. They're invite only + places are limited, so brands only ask the media, buyers + essentially anyone who is likely to put money in their pocket, or direct others with money to them. Fashion shows, sadly, aren't a spectator sport. In recent years there has been a rise in ticketed fashion shows, these are fun to go to if you fancy it, but are by no means an industry event. In my 13 year career in the fashion industry, I've worked over 50 fashion shows, but have attended only 2 as a guest. Both of which were a kind twist of fate; the first was a chance meeting of a member of the Alex Perry team in Australia, the second with Burberry creative director Christopher Bailey, who visited the same University I attended (he's from the area originally). Aside from those 2 experiences, my view of fashion shows has been the stressful backstage area, doing damage control which has included sewing garments onto models, gluing them into shoes + many, many staples.

Misconception 2; When I've 'made it' I can design whatever I want

That would be nice, but sadly no. Sure, you could start designing whatever you'd like, if you wanted to, but the chances are that this wouldn't be good for business. For example, let's look at a large retailer I worked for. In the design team, we loved coming up with exciting new concepts and trying new things. We always made an effort to show some new + exciting styles in the collection. The press generally loved them, but the customer response was often lukewarm. Our bestsellers were the basics, classic styles that we had made for years. This is often the case - people have limited funds + often choose the practical items over the extravagant 'will be worn once' items. Not very exciting for the designer, but we have to work towards a profitable range. You may have also read in Wednesdays post about things that we have to consider as designers (if you missed that post you can read it here). These considerations of commercial viability, how the garment will be made + sold will always have to be followed if we want to have a profitable business.

Misconception 3; When I'm the boss, I can just do the fun stuff

Erm, no. While I'll admit I am somewhat of a control freak + take on more tasks than I should, there's a lot of boring, but important decisions to be made + I don't want someone else having that much control over my company. If you own a fashion brand you'll have a lot of seemingly dull tasks to do that you'd probably love to hand over to someone else, but you need to think about what's best for your business + also how you'd feel if someone else made the wrong decision. For example, quality control. This can be very tedious, but do you really want to give someone else the final say on what quality is acceptable for your brand? Another example is cost prices, a lot of people hate the thought of numbers + an excel spreadsheet, but do you really feel comfortable in paying bills for things you're not involved with? For one, there might be a cost saving opportunity that an employee (who doesn't have to pay the bill!) hasn't explored, or worse, a dishonest employee could be giving business to someone they know, rather than the person best for the job. If you can only commit to one boring job, it has to be finances. I've literally seen companies with large sales go into bankruptcy because the owner didn't have a handle on the expenses.

Misconception 4; I won't work any overtime

You must be dreaming! If you've worked in the industry before + know how much unpaid overtime is required, you may start your own company vowing not to do that to yourself. When I started this business, I myself had the same hope, that my own business would mean achieving that elusive work-life balance. No chance. When you have your own business, sure you can take time off when you need it, but at the same time you're never really off work. It's not an option to put an out of office on, without it having a detrimental effect on your business. The same goes for in industry, a friend of mine is at the very top of the chain, she's the Director of Womenswear + she gets calls, emails + video conferences at weekends + holidays. What I will say is that, working for yourself, there is the hope that it's all worth it in the end, as it'll be you who is benefitting from your hard work, rather than the shareholders or your boss (fingers crossed!).

Misconception 5; I'll host lots of glamorous parties

You could, but do you really want to pay for them? Not to mention have the stress of organising them, knowing who to invite without ruffling anyone's feathers + making sure the event is a success? It might be the right decision to host a party for your business, maybe a launch party to show press the new range, or a shopping night for your best customers. The thing to remember is this is unlikely to be a fun evening for you. There'll be an agenda + a reason that you're spending money on this party for your business. You'll need to stay focused, even if you've hired people to run the party in terms of food, decor, etc. It won't be an opportunity to relax + have drinks, you have to be on form, making a good impression + subtly encouraging people to do whatever it is your goal is for the night, be it sales, features in the press, or an increased brand awareness. If you're looking for a fun crazy party, I'd recommend calling your friends, rather than colleagues. Sorry to be a buzz-kill, but I warned you I'm a realist!

Is the fashion industry really for you?

Don't get me wrong, I love the fashion industry. I don't for a second regret giving up a law career + there's nothing else I'd rather do. But there are days I want to tear my hair out, other's when there's no chance to sleep (my current record is 38 working hours without sleep) + weeks where I've worked over 130 hours (I didn't realise there was that many hours in a week, either). I suppose I felt obligated to write this post to let you know that, behind all of the styled photos, mood boards, international travel + creativity there's a lot of hard work + always will be. It's not for the faint hearted + there will be times that you have to choose work over friends + family. A few things to ask yourself; 'do I love the idea of having a fashion career so much that.....'

I'm willing to stay up all night

I'm ok with checking emails on holiday

I will cancel plans with friends + family to work

I'll accept that there's always more work to be done

I'm ok with getting negative feedback from people

If you don't agree with some of the above, it might not be the best industry for you to work in. If this is the case, it does't mean you have to give up fashion all together. You could have a fashion business as a side income, so there's no pressure to make a living from it. Or you could keep it as a hobby, which might not be what you want to hear, but if you value your free time, this might be for the best.

I apologise if I've scared you a bit with this post, but I feel that it's best to be prepared, so a few years down the road you're not wondering what you've let yourself in for! If it's had the opposite effect + you can't wait to get started in the fashion industry, but not sure what step to take next, I might have just what you need. My Fashion Startup online course walks you through the process of going from fashion idea through to garment production, step by step. You can learn more about The Fashion Startup Online Course by clicking here.

What goes in to my fashion design service?

Think a design service is someone drawing pretty pictures? Think again! This post covers the many things that go into a design, from financial considerations, to trends and manufacturing...

On the surface of it, you might just think 'oh, design service. Someone will design pretty clothes for me'. I wish it was that simple! The scary thing is that this is a common misconception about the fashion industry, even from designers who haven't worked in the 'real' side of fashion. It is a business and as such, absolutely everything you do has to be business focused. It would be lovely to just design whatever you'd like, but the reality is that each item must sell for a good profit, otherwise you'll find yourself bankrupt in little to no time. Even the multi-millionaire daughter of a Beetle, Stella McCartney, has to design around a business focus in order to sustain a brand.

I've been fortunate enough to work in lots of different areas of the fashion industry and this has led me to work in a different way to many others, because I foresee the production problems while still in the design stage. If you've never been a pattern cutter, sample maker, or production manager and have always stayed in design, it's easy to keep passing your designs on, blissfully unaware of the nightmare that you're causing the factory. So when I'm designing a range for you, what do I take into consideration?

1. Who am I designing for?

This is where you, as a client, can be very helpful. The more information you provide on your target customer and the type of brand you're trying to create, the more I can tailor the designs to you. I provide a designer briefing sheet to help you get your ideas and customer across, be as detailed as you can with this. I'm sorry if it feels like I'm giving you homework, but it's for the best, I promise! Let's take an example. A customer approached me to design a new swimwear line and sent some examples of string bikini styles they liked, but didn't want to tell me anything about their customer. So I took inspiration from the string bikini. They later told me that the range would be available in plus size cups.....had I known that before, I would have told them why a string bikini isn't a good idea for this market and would have designed accordingly. I wouldn't have expected them to know this, 'you don't know what you don't know', but if they had been open about they're customer I could've created better designs, suitable for them in particular.

You might feel that some of the questions on the sheet are a bit useless, but in all honesty I developed that sheet after years of experience and can assure you that each question is totally valuable, so the more you can tell me, the more I can work for you specifically.

2. What is the price range

One of the questions you might find odd is 'retail price range', you might be thinking 'well, the price will depend on the price I get from the factory'. Please never think this and don't allow the factory to dictate your retail prices! I'll be covering this topic in more depth in an upcoming blog post. You, or your market research should determine the retail price. For example, if you'd like me to design a range to sell for £10-£50, the fabrics and techniques I choose will be very different to one that sells for £70-£300. To the client, it may look as though the price doesn't really affect the deigns, but this isn't the case at all. Subtle variations, such as construction and fabrics can make a huge difference to the price, all of which are considered when I design. I like to present designs to clients that are commercially viable and it's no help to anyone if I present 100% silk styles to someone who wants to sell for £30 - they will never be able to get this into price.

3. How will this be manufactured?

Each design I submit has been considered from a pattern cutter, sample maker and factory perspective, even if you're not getting any technical services from me. I see so many designers submitting work, which ends up coming to me for correcting, as the designer hasn't considered how to make it and later realise it's not actually possible. Let's take a simple example, a customer came to me recently for a consulting session. Someone had done designs for her, but the factory we're really struggling to understand what they were making. The answer was simple; the designs didn't have a back view, an individual view (coats were covering the tops, so you didn't know if they were long sleeve, short sleeve, etc) and as they were presented as fashion illustrations, they were disproportionate. I love fashion illustrations and think they could be a great addition to branding, marketing, social media accounts, etc. However, in the manufacturing world they are very confusing. Fashion illustrations are usually disproportionate and are essentially 'stretched out' about 20%, so the legs and torso are much longer than on a real body. This makes it hard for anyone trying to produce the garment to identify the true proportion. That's why I always present my work as 'flat' CAD drawings that are easy to understand and provide a front and back drawing as standard. I appreciate this doesn't look as exciting as a fashion illustration, but you have to ask yourself if you want exciting, or if you want to actually get a finished piece of clothing.

I also consider things further down the track, into pattern cutting and production. This is something that you won't see in the designs, as basically I won't send anything to you that'll be really hard or impossible to produce. This makes it easier for clients, as they don't have to consider their factory, they can just make selections based on personal preference.

4. When is the range for?

Another question I ask is, when are you launching the product. This is both so that I can take into account any trends and also so that I can choose suitable fabrics and make sure the collection is seasonally appropriate. Something important to note about trends; I don't believe in being a slave to them and the use of trends will come back to the target customer. I believe there's a big difference between 'trend led' and 'trend relevant'. For example, if I'm designing for a fast fashion company appealing to 16-25 year olds, trends will play a key part in the design process. If, however, the range is evening wear for the over 50's, trends will still be considered, but they won't be the driving force. In most cases, unless the client requests differently of course, this type of design would be something I call 'trend relevant', meaning the designs fit in with the season's styles, but also have a timeless quality and won't date quickly.

5. How will this work together as a range?

'Range building' is one of the most important things to get right, in order to increase the company ATV (average transaction value), UPT (units per transaction) and generally lead to greater profits in the business. By making sure that the collection works together as a range and is interchangeable, you can encourage customers to make additional purchases. For example, they might be looking for a top, but could end up adding the trousers and/or jacket to complete the look. Or, they might buy the kaftan that compliments the bikini set. The other thing to consider when designing a range, is how many of each category (e.g; top, bottom, dress, etc) and also the price (again!) structure. I look into sales data for various market sectors and will use the one relevant to the target audience I'm working with to decide on both the breakdown of categories and also how many items are low, medium and high priced (whatever those prices may be according to the client's retail price range). This can all get a bit overwhelming (sorry if I lost you at ATV), but essentially, I can worry about this so you don't have to.

6. How will this be perceived by the press and buyers?

Another thing to consider is how the collection will look to professionals. Of course, the range will be customer focused, but in order to get the product in front of customers, it needs to get some publicity. This is also a reason to keep the range trend-relevant, even if you're not interested in being trend focused, as magazine editors and bloggers will be working to a specific theme. Press are also inclined to seek 'special' pieces, known to designers as the 'press piece'. The press piece isn't usually the bestseller, but it gives the brand exposure and publicity and is a style that customers aspire to own; more on this topic in a future blog post. Buyers will of course consider price, but also how the clothes work together and how they can be merchandised (displayed together for maximum impact and profitability) in store. I, therefore, also consider these things in order to produce a fashion range that can appeal to press and buyers, as well as your customer.

I wanted to clarify that all of the above is included as standard with any designs that I create. Essentially, you're getting advice as I'm considering all of these things for you, but we're not necessarily having a discussion about it. This allows you to choose designs in confidence, based on your personal preferences without having to consider all of the above. If you want to make some changes but not sure if they'll work, I'm more than happy to tell you if they're suitable and achievable.

I hope this post has given you some insight into all of the decisions and considerations that go into each and every design I create. If you'd like to ask any questions, you can send me a message here. There’s also a full list of the services I provide, which you can view by clicking here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

How to give sample comments to your factory + perfect your fashion range

This post covers how to give your factory feedback on changes that you would like to make to your samples, following on from your fit session....

So, you've held your first fit session - great! (If you missed the post on how to hold a fit session + make the most out of it, you can read that here). Now what? You need to effectively communicate your changes to the factory, so they carry out your instructions, perfect the garment and avoid any extra samples having to be sent. This post goes through the steps that you can take in order to achieve this and also things to look out for.

How do I communicate changes?

Use the columns on your tech pack and fill in the columns relating to the sample. So for example, if this was a pre-production sample (PPS), you would complete the column for 'PPS' (where you enter the measurements of the sample you have received,' +/-' (where you enter the measurement differences between what you asked for and the sample you've received) and the 'PPS amended spec' (where you enter the measurements you would like following the fit session.

You may also need to send written comments relating to the measurement changes, especially if any of these are quite different, or if they have been made to correct a problem with the current sample.

If there are issues with the sample, for example the hem is uneven or there are problems with construction, it's often best to include photos of the issue and some accompanying text. If it's an issue to do with shaping, for example you don't like the curve of the neckline, you can draw the actual shape you would like over the photo.

If there is a problem area, it can be helpful to add extra measuring points. This can often be helpful with complicated style lines or for problems at curved areas such as the armhole or hips.

For the extra text and/or photos, these could either be added to a new sheet on the tech pack itself, or as a simple word document. Personally, I add a sheet to the tech pack (nothing fancy, I just add a blank sheet, write the sample and date at the top and list my changes), that way, I can easily refer to the comments when the next sample comes in and it keeps everything in one place.

On the tech pack page, I highlight the measurements the factory should be following for the next sample in yellow and make any measurements to be changed in bold so it's easy to see.

In the main body of the email when I send the comments I include any major issues in bold, to ensure they are addressed.

Sometimes, the sample may not measure 'to spec' (as per the measurements you requested), but you may be happy with them anyway. In this case, I make a note of this to say the spec has changed, but the measurement has been approved as per the sample.

I've put a couple of screenshots below to help you understand what I mean in the points above. You can click on the images to increase the size if you're struggling to read the text.

Example of a comments page I added to the tech pack

Example of highlighting the measurements to follow and using a bold font for measurements that need changing.

What kind of language should I use?

This can vary between factories and countries, but as a general rule, if you are working with a factory who's first language isn't English you should be direct and specific, don't leave anything to the imagination. In general, either way, don't write as you would speak, there's no need for lots of extra words. Bullet points work best, so manufacturers can easily see the problems and fix them one by one, rather than having to trawl through a long message in order to find the problems. People are busy and the more extra words there are, the more easily it is for things to get missed.

Particularly for non-English speaking manufacturers, be blunt if need be. It feels strange to most of us being very to the point and simply asking someone to do things better, but with many overseas factories if you're not explicit in what you want and when you want it, they often consider it to be unimportant and things can get missed. If something hasn't been done that should have been, don't be afraid to write in bold and capitals to make sure it won't get missed again - it can take some getting used to, but in my experience it does lead to better results.

Don't expect the factory to solve the problems. This is often a point that a lot of new brands struggle with, as they expect the factory to offer all of the solutions. If you have a good factory they can certainly help and make suggestions, but don't forget they are making money from you and may guide you in a direction that is more profitable for them, rather than being best for you. If something is wrong, don't just say fix it. Say what you want to happen. For instance if your fit model is struggling to get something over the hips, but when its on it looks great, don't just say 'garment is hard to get on' say 'zip is 15cm too short, amend in next sample', and add the new zip length to the spec sheet.

Think of the consequences

When writing comments, one of the most important things to consider is 'what is the consequence of this change I am making?' Again, this is one of the things that new and inexperienced brands can find challenging. Often things aren't properly considered and when the next sample comes there's often a situation where one issue has been solved and another has been created. To explain my point more clearly, I've written a few example scenarios below;

If you have a top or dress with a sleeve and increase the 'cross shoulder' measurement, this could mean the sleeve is then too long. Why? Because causing the shoulder to be wider, means the sleeve will start further down the body and as the sleeve length in this example has been kept the same, it would mean the sleeve appears to be longer, as it sits further down on the arm. To compensate for the wider cross shoulder, you would need to reduce the sleeve length if you want it to sit in the same place as your current sample.

If you read my previous posts on tech packs and samples you've probably heard me advise to have all fit samples in the correct fabric. If the fabric on the sample is different, or if you decide to change it, you have to think of the implications of that. For example, if the fit sample is in a really stretchy fabric and you take a lot out of the measurements in order to get a fitted look, you may find the item is far too tight if the correct fabric has less stretch in it.

If you change the armhole drop measurement (the distance from the highest shoulder point to under the arm), you need to remember that some other measurements are based on the position of the arm hole, for instance, bust, waist and hip measurements are often 'x amount' of centimetres/inches below the armhole. If for example you make the armhole 4cm lower, then you need to remember to change the measurements so the 'x centimetres/inches below the armhole' is 4cm less. Otherwise, the bust, waist and hips will be measured too low.

Wow - that was a lot to take in and can be really overwhelming if you're new to this! I hope the examples have made things a bit clearer, but please feel free to comment below, or get in touch here if this is all too much and I'll try and explain it differently for you.

If you don't feel confident in completing comments yourself at this stage, I offer coaching online and in person fit session help (in several cities worldwide) and would love to discuss your project further. If this is of interest you can send me a message and I'll get back to you with more information.

What size range should I make my fashion designs in?

Getting your fashion designs produced and thinking there's a 'standard' size range? Think again! Learn how to choose a size range in this post....

The answer may seem obvious and you might even be wondering why I'm writing a blog post on this. But in honesty, choosing the right size can make or break the success of a range and isn't a decision that should be taken lightly. When I'm providing technical services for my clients, one of the questions I ask them is 'what size range are you making' and far too many of them answer 'whatever is common', or something along those lines, which is why I'm writing this post. I hope to explain why the term 'common' or 'most popular' are redundant and why it's up to you as the brand owner to establish what your customer's needs are. I'll also talk about things that can help you when choosing a range and points you should consider.

Why can't I make it in the 'common sizes'

The trouble is when people ask me this is, what is a common size? Often when I'm doing a tech pack I'm simply translating their designs into a technical format, with stitch details, trims and the like, so I don't actually know much about the customer profile when I do this kind of work. What is considered to be a common size for one area of the market, or world, may be a bad seller in other areas. Let's take an example; I used to work for a mid-level retailer aimed at reasonably wealthy families in England. Our bestselling size in Womenswear was a 16. Another company I worked for was a high end fashion label in Australia, their bestselling size was an 8 and we could barely shift size 14, so we didn't make a 16. If the Australian brand had gone with what was a 'common' size range, they would have been left with a large amount of size 16's they wouldn't be able to sell, resulting in left over stock that they've made a loss on. So you see, you really have to define your customer and their needs in order to make a good decision.

How can I determine my size range?

There's a number of key factors to consider when choosing a size range. I'd strongly encourage you doing as much market research as possible with your target customers as this will make the process a lot easier.

If you've already sold products before for the same brand, the sales data is your best friend. Ask yourself, what sizes were left over when you went into sale? Did some sizes have a better sell through percentage than others?

What's happening in the industry? Is there a gap in the market for a particular style/sizing, for example activewear for tall people or sleepwear for plus size?

What is your customer saying? Engage with them on social media or in stores, what size are they looking for, do you stock it, has it sold out?

What are your competitors doing? When I say this I mean specific competitors, i.e. they sell in the same market as you. For example eveningwear in the US or sportswear in India (which, incidentally, is booming at the moment).

What is a size break?

A size break is the percentage of the order that is allocated to each size, or the size ratio. So for example, you might place an order of 500 units and order 50 XS 200 S and 250 M, this is the size break. A factory will need to know this when you place your confirmed order, as the size break determines the amount of fabric that is required. Of course, the bigger the garments the more fabric is needed, so if you're looking to make plus size garments tell the factory as soon as you can as there may be a surcharge. Also keep in mind that if you're placing small orders a factory my limit you on the number of sizes you can order, as it is extra work for them to create each size and they may not be willing to cover the cost of that if they're not making may items for you.

As with choosing a size break, there is a lot to be taken into account. Use the 4 guidelines I mentioned earlier to help and keep a close eye on sales. This is why I always recommend that new brands start very small, in order to establish the demand and order the correct sizes.

What are size outs?

You may not of heard the term before, but I'm sure that at some point everyone has come across size outs. When you go into store, or shop online and your size is no longer available, this is a 'size out'. A size out is when the retailer has ordered the wrong size break and has sold out of the popular sizes, while other sizes are still available. This can create problems especially in physical stores, as obviously they still need to display the stock to sell it, but it causes lost sales and disappointment when customers find out their size is no longer available. Good communication with your customers and close monitoring of sales data can help you to avoid this situation and remember that your customer base can evolve over time, so don't be afraid to make changes, or at least do some trials if need be.

I hope this post has given you some answers and things to consider. If it's left you feeling confused, or you're not sure of some of the terminology please feel free to leave a comment below or contact me here and I'll see what I can do.

Ultimate guide to fit sessions for your fashion business

This post will help you organise a fit session and use it to improve the look and fit of your fashion garments....

If you’re manufacturing your fashion line and want to perfect the fit, you’ll need to be familiar with fit sessions. Fit sessions are super important to get right if you want customers to love your product and be able to easily find their perfect size (and in turn, hello low returns rate!). Fit sessions are used in conjunction with your tech packs (which you can learn about here) and the two things combined help you to get that perfect fit for your products. In this posts, let’s find out what a fit session is and how to run one correctly, to ensure that your fashion garments fit well and look amazing.

What is a fit session?

A fit session is a meeting involving the fit model, a garment technician (like me) and someone from the brand (you!). A fit model is an employee or freelancer who has the measurements of your average customer. The fit model will try on any fit samples from the factory, so you can assess the fit and decide if it is suitable for your customer. During the meeting, fit samples (samples sent from the factory at various stages of development, to check the fit) will be tried on by the fit model. The buyer/designer will comment on the overall styling, fit and quality of any trims or fabrics sent for approval. It is the garment technician's job to make a note of what has been approved and what needs to be changed. This information is recorded on the tech pack and will be sent to the factory so they can work on any amendments, or make the final order if the sample has been approved.

How do I prepare for a fit session?

You will need to know, or organise the following in advance of the meeting;

Before the meeting, I would measure the garment, so you can check how it compares to what you have asked for in your tech pack. This will make it easier for you when you come to feeding your comments back to the factory.

You will need to book time with your fit model and make sure you have space for them to change, wherever you are holding the meeting

You will need to bring the sample that needs fitting, as well as any previous samples as they may need to be referred to

Tech packs for each of the styles you are fitting. This could either be a printed document or on your computer, whichever you will find it easiest to refer to and make notes on

Personally, before going into a fit meeting I like to familiarise myself with the situation; things like, which sample we're on, any problems we've been having and how long we have until the item ships, are all useful to know

If the sample is made from alternative fabric (i.e. not the actual fabric you will be using for bulk) you will need to bring a sample of the actual fabric and any trims, if you have approved them. Note; wherever possible samples should always be in the correct fabric.

You should bring a tape measure and have enough space on your phone for photos!.

What should I look out for in the fit session?

The purpose of the fit meeting, or 'fits' is to make the garment as close to perfect as possible. Unfortunately, it's not always possible to correct every issue, but the idea is to make sure the garment is suitable for your customer. You're not only looking at the styling to see if it appeals to them, but also at things like the fit and how it feels when it's worn. If it's supposed to be for work can you sit down in it comfortably? If it's meant to be for sports is it stretchy, can you move easily? Is the fabric pulling and creating drag lines? Over time you will develop an eye for detail, but here's some initial things to look out for to start you off;

Look at it from a customer perspective. If your customer saw this in a shop, would they like it? Would they want to try it on? Does it give the impression it's well made?

Look at the stitching, is it straight and neat, or is it wobbly and inconsistent?

Ask the fit model how it feels. Ask them to move around, look out for common problems such as restrictions on moving your arms forward, or things (especially trousers/pants) being uncomfortable when you sit down.

If the garment is meant to be fitted, is it saggy anywhere, are there any drag lines (where fabric 'bunches' together)

Is this the right size for your fit model? If not, change the measurements so it is a good fit.

How about the length? Is it working for the look of the garment and also in terms of practicality?

Are all of the components working together, such as styling details, buttons, pockets? Does anything look over the top or out of place? Or do you feel something is missing?

Can the model get in and out of the garment ok? Is the zip long enough, is it good quality or is it getting stuck? If the garment uses buttons, are there enough, or are there gaps where you can see the model's skin?

Essentially, you are looking for anything that will either affect the performance of the garment (such as zips that get stuck, or seams that are coming apart), or things that will stop your customer from buying it (like it restricts movement, or is uncomfortable to wear).

How often do I have a fit session?

Here, I would love to write 'as many times as you need to', but unfortunately it's not always that simple. When time planning, I always allow for 4 samples and fit sessions, but aim to only need 3. A first fit, pre-production (sent for final approval before the stock is made) and a shipping sample (sent after the stock is made but before it is shipped so we can check for any issues before it leaves the factory). To reduce the number of clothing samples you’ll need, giving clear instructions to the factory is essential, as they are often unwilling to use common sense or imagination (sounds awful to say but sadly that is often true), so make sure you're very specific about what you want. I’ve heard of some people who aren’t as experienced in fittings and don’t have detailed tech packs needing as many as 9 samples, so putting in some work upfront really does pay.

The other things to consider are how much time do you have and are you paying for samples? If you're a startup or small business, the factory will often charge you for the samples, so you need to decide how important the changes that you'd like to make are vs the cost of an extra sample. In terms of timeframe, if you're asking for extra samples, this may cause a delay to the delivery, so again you will have to assess how critical the changes are vs the delivery date into store is.

I hope this has given you a few ideas for things to look out for! If you're finding the process a bit overwhelming and are looking for detailed guidance and step by step help with the fashion manufacturing process, you might be interested in The Fashion Startup Online Course, which has a whole module to cover the sample process and another dedicated to working with factories and the process for production. You can learn more about the course by clicking here.

Thanks for reading! Vicki

The ultimate guide to CNY (Chinese New Year) for the fashion industry

What is CNY and why does fashion production shut down because of it? This post covers what to expect and how your fashion business can prepare for it....

Gong Xi Fa Cai! Happy Chinese New Year! If you've been in the fashion industry for a few years you'll have heard that phrase over and over, but if you're new to the industry and wondering why you've not heard back from your factory in about 6 weeks, here's what you need to know.

What is CNY?

CNY is industry slang for Chinese New Year. It's something that you'll probably come across for about 8 months of the year from your less reliable factories, as they tend to use it as an excuse for delays. The Chinese celebration of New Year is very different to Western culture, as it's a celebration much more than a New Year's Eve party for many of the population. In the fashion industry, factory workers are allowed to take up to 8 weeks off in order to travel back to their place of birth and visit family. I've heard reports from factories that I've worked with that some employees literally walk home over several days or even on some occasions weeks, in order to save money on public transport, or due to overcrowding. I have to be honest in saying that I'm not sure to what extent this affects people and factories I work with are always paid a fair wage, so I'm not sure of the underlying issue here, but it's something that I want to learn more about. If you're working with factories in China, you'll probably find that your merchandise contact is available for most of the holiday, but most likely you won't receive any samples during this time.

Huge Dragon lanterns at a CNY event I went to this year

When is Chinese New Year?

The actual date of New Year varies each year. This year it was on January 28th and next year it will be on February 16th. As the Chinese calendar is Lunisolar, the date can vary between January 21st and February 20th and the first day of the New Year is on the day of the new moon. The holiday taken by factories varies between regions and will also depend on the factory owners. It's best to ask each factory you're working with when they'll be on holiday and for how long. In order to avoid any disruption during CNY, you need to be asking this question 4 months in advance at the very latest.

What happens during Chinese New Year?

In terms of the industry - not much! As I mentioned it's unlikely that you will receive samples of any kind, or even quotes during this time so you might find yourself unnervingly quiet! So this time of year is great for looking at your brand strategy, designing new styles, or just generally getting on top of filing and all those tasks that get missed during what we call the 'pre-CNY rush'. In China and other regions that celebrate CNY, the main event is the lantern festival. Depending on the region, the celebration varies, some are more traditional and honour deities and ancestors, while others have a more modern approach and have a meal with their family and exchange money gifts in red paper envelopes. You can learn more on the traditions in this article.

Wishing you a happy and prosperous year of the Rooster!

How can I prepare my business for CNY?

The key here is in the planning;

The majority of fashion labels will plan their range 6 months in advance. When ranging for styles coming into store/online in February/March, this needs to be increased to 8 months.

Even January and April need to be considered earlier if possible as well, due to the pre/post-CNY rush.

Also keep in mind that the ports will be shut, so even if your stock is ready, you need to make sure that the port is still open so that you can still ship the goods.

Make sure that the factory are aware of your timelines and also get as much information as possible on what will be closing when - often the dye mills close first, so it's a good idea to prioritise any lab dips.

Keep a close eye on your timelines and in particular your critical path, chase any styles that look as though they are falling behind to make sure things stay on track.

Hopefully, this all makes sense and offers some useful and actionable advice to prevent delays to your range next CNY? Or, if it's got you into a bit of a panic and you're thinking 'a critical WHAT?' don't worry! There's plenty more posts coming!

Did you have any issues this CNY? Or maybe you were one of the ones celebrating? I'd love to hear about it in the comments box below.

Happy Year of the Rooster!

How to use and complete a tech pack for your fashion design

Demystifying the tech pack; what the terminology means and how to fill the sheet in.

Last week, I wrote a post on tech packs - why you need them and what they include (you can read that here if you missed it). I mentioned that the tech pack is a working document that needs to be edited and updated over time. This can be quite daunting for people new to the industry, especially those who think they can hire someone to make a tech pack and that's it, there's nothing more to be done. This post goes through the information in the tech pack in it's earliest form, what it means and how it can affect you.

For this post I've used a basic examples of spec sheets I've created. Of course, different garment technologists will have a different approach, but this is the basic template that I use for spec sheets I create for my freelance clients. Even if the formatting is different in other tech packs, the overall content and the key things to look out for will remain the same. You'll notice that in each box I've written some suggestions. I tailor this for each of my clients to give them a guide, so please be aware that the information on this spec sheet may not be relevant to your situation. I'll go into more detail on this in a moment.

Here’s what should be included in your tech packs;

Colour, pretty obvious but do be sure to update it if the colour changes

Fabrics, these may start off as fabric ideas and the fabric will be confirmed at a later date (more on that in this post). When the fabric is finalised, be sure to add the composition and weight, plus any codes or reference numbers

Delivery date - be clear what you mean here - delivery date to you, the port, the airline? Be specific about where the stock should be delivered and when

Trim and label information - when the fabric is confirmed a care label can be created. You'll need to specify where you want this and any other brand/size labels. You'll also need to specify which labels to use and who will be providing them

Samples required - the more samples you can get the better, but of course the factory will only agree to so many. I like to have a good sample of sizes so I can check the fit across the size break, but this isn't always possible depending on what you've agreed with the factory. After you've discussed how many samples you can have, you can enter your size requirements here. The size you ask for will depend on your brands customers, your fit model and your advertising model, if you have one.

Lead time - how quickly you expect the factory to send the next fit sample, after they've received your spec sheet (in the first instance) or fit comments. The length of time will previously have been agreed with the supplier in your contract or service agreement, but it's good to put it here as well so the person working on the development is aware and there's no excuses for it being late.

Packing information - these requirements will often be set by your distribution centre, or you if you will be the one sending out orders to customers or stores. For example, some companies are not set up to receive hanging stock, everything has to be flat packed. Some will even specify the maximum size of the package.

Fabric testing - if you wish to carry out any performance tests on the fabric, you can note these down here.

Packaging information for the cartons - this information will come from your freight forwarder (or courier service for small scale businesses) and your distribution centre. Different companies will have different information that needs to be on the box, you only have to fill in the information required and the factory will enter the rest, for example, how many items are in the box, the weight, etc.

REF refers to the letters on the diagram

Measurements shows the point of measure. You may amend this as you go through the fit process, if you add or remove elements.

Original measurements will be for your chosen fit sample size and the first fit sample will be made to these specifications.

1st fit, 2nd fit, PP, etc - in this column you write the measurements of the garment that you receive from the factory

+/- in this column you write the difference in the measurements between what you've asked for and what the sample actually measures

1st amended spec/2nd amended spec - after fitting the item, you will use this column to request changes to the next sample. There can be a lot of changes throughout the fit process, so this is really important. It's impossible to get a great fit the first time, because it's hard to predict how the fabric and components will react (especially as the spec is usually done before the fabric is confirmed). Things like the weight of the fabric and amount of stretch can make the fit dramatically different, so make sure each sample is sent to you in the correct fabric.

Final spec - when you're happy with the way the garment looks, enter the measurements of that garment in here. The factory will use this to make bulk.

Shipping sample - the factory will send this for your final approval before shipping the stock

Grade rules - these will alter depending on your customer and market. Grade rules dictate the difference between each size. If you're able to get extra samples made up by the factory so you can check that the style works in each size, that is preferable. If not, try to look at your market research and see any patterns in your customers measurements, particularly those who wear the same dress size. You could also ask the factory for information on products they've done for other customers in the same market.

Tolerance - this is the maximum amount of difference that you are willing to accept between what you have asked for and what you receive. For example, if the measurement should be 40cm and the tolerance is 1cm, you may receive a garment that is 39cm or 41cm. This can alter the cost price a lot and generally the numbers here will be smaller for high end ranges and higher for budget garments. Tolerance is often something that is discussed at the contract stage with the factory as it's good to outline your expectations from the start.

Construction comments - these may need to change depending on the factories capabilities and the equipment they have. They might also have to change if the cost price is coming out too expensive and you need to use cheaper methods. Often components such as zips and buttons will be included here and will need sourcing, when the component is confirmed the specifics will have to be noted here.

Not everyone will require page 3 as this is for any placement prints or embellishments, if the print or beading is on the fabric, this will fall under page 1. Page 3 has the specifics of the technique needed and the measurements of the placement. The information on this page is quite straightforward and will just need to be updated if the print size changes and the print method will need to be added here when confirmed.

Extra pages

Sometimes there will be a need for additional pages, depending on the design and also the requirements of the company. Some may ask for an inspection of bulk, so a page will be created for the factory to write down their findings. Some people prefer to add an extra page for fit comments and space for photos. There can be variances but these are the key details to look out for.

If you're planning on producing a fashion range + need help with tech packs, you can learn more about the service I provide and how it can help you, by getting in touch here. My tech pack format is tried + tested + has been used to get hundreds of products into production, for both startup and established brands. Alternatively, you can see all of the services I provide, here.

I hate spam too - if you sign up to this email list, your details won't be sold or leased to anyone else. I will email you from time to time with helpful content and occasional offers, which you can unsubscribe from at any time.

New services; the complete package for new fashion lines, with consulting help

New services available for startups and small businesses who need help with their new fashion range....

I recently read an amazing article on the Business of Fashion website (a great resource and I'd highly recommend subscribing to their mailing list if you want to know whats going on in the industry) about launching a fashion label, which you can read here. It made some excellent points about the traps that many people fall into. It's so easy to get carried away with ideas and rush into things, but the reality is that a fashion brand is a business, people can't be successful on ideas alone. “To be honest, I don’t know how (other) young brands can start without any business experience,” says Laura Kim, at Oscar de la Renta and I agree - dealing with factories, technical specifications and shipping profiles can be exhausting and a real drain on your creativity. Another quote I found spot on was “The time of self taught maestros has come and gone,” says Luca Solca, head of luxury goods at Exane BNP Pariba. This article has spurred me on more than ever to try and help small and startup labels to get some helpful insight into the very secretive fashion industry.

Who are the new packages for?

My new packages are aimed at those who would love to have their own fashion line but aren't sure where to start, or perhaps they lack experience in the technical side of fashion. I do still offer one off consulting sessions, but the packages I’ve developed have been carefully curated to give a better overall result. The packages all include one-on-one time with me, so we can really look in detail at your situation and identify problems early, so they can be avoided - you're essentially learning from my mistakes! I'd love to say I purposely made all those mistakes with my first business as a cautionary and educational tale for you - but sadly no, I was just young, excited and inexperienced! The packages are completely tailored to your situation, so it doesn’t matter what stage you’re at, or what you’re struggling with specifically, we can create something that works for you. For more information on how I can help, click here. Alternatively, you can send me a message via this link.

Who are you?

If you're new to this website you're probably wondering, who is this person and why does she think she can teach me stuff? Sorry; I'm Vicki, founder of 29andSeptember Studio. I've got 12 years experience in the fashion design and production business and have worked on ranges from their initial idea right through production, merchandising and selling in store. Now I help a range of clients realise their dream of owning their own fashion label by educating them on the ins and outs of the fashion industry. You can learn about my story here if you'd like. On the less formal side, I love to create, decorate my house, eat Ben and Jerry's and drink lots of tea (English tea, like me).

What do I get in the packages?

I now have 4 packages all carefully designed to help with a specific need. As I mentioned, each package includes mentoring time, which can be used to address the issues you're most worried about, or the area of the business your struggling with. I can even look at emails and documents from suppliers if you'd like and we can go through them together;

Range review; I can go over the designs you have created and identify potential problems, both with production and also selling the product to customers

Monthly coaching package; this service allows you to have regular coaching sessions so we can review your business, progress you've made and set targets for the future. It'll also help with action steps to get you closer to your goals.

Complete production package; if you've finalised your designs are are ready to get them made, this service will provide all the tech packs and documents you need to get your samples made. It also includes education on the production process and tips for a successful end product

Complete design + production package; this includes a custom designed range perfect for your customer and style, plus tech packs and help with approaching factories and getting the deigns made.

This gives a really brief overview of each package, as always you're welcome to ask me any questions, or you can read more about ways of working together, here.

I'd love to hear what you're working on at the moment, or what your current aspirations are - if you're happy to share there's a comment box below...

Thanks for reading!

What is a tech pack and why you need one for apparel production

This post explains what a tech pack includes, why it is useful and why you need one for your fashion business.

A tech pack can go by many different names, such as technical specification, specification pack, spec pack, BOM (bill of materials) or GWS (garment work sheet). Essentially it is a document referred to by you or your garment technician and the factory or person making your patterns and manufacturing the clothes. I find a lot of my clients have heard of the term tech pack, but don't really know what it entails or why they need one and often wonder if the factory should do it. This post is to explain what a tech pack is and why you need it.

Common misconceptions

'I don't need to pay for the spec sheet, the factory can handle those' - I hear this quite often and to be honest it scares me! Essentially, a tech pack is about control (we'll dive a little deeper into this in a moment), do you really want to be giving the factory control over the measurements and finish of the garments? The problem with the factory doing the spec sheets is that they will often do what is easiest for them, this is especially true if you are inexperienced and don't know what to look out for. Certainly, if the factory offers suggestions on ways to improve the garment, hear them out, but make sure the final decision is down to you. Also keep in mind that, the factory are a business looking to make an income. If they do the spec pack, it would be easy for them to choose more expensive methods they can charge you for, if they are that way inclined.

'Once the tech pack is done, that's it' - sadly, it's not that simple. Tech packs are a working document that are updated regularly over the duration of the fit and manufacture process, which can take around 4 months. The tech pack you receive from your garment technologist, or a freelancer you hire, is effectively the first draft. Even before the first fit sample is made, it may change. This is because the factory need the tech pack to quote a price. You may find the price is too high, so you make some changes, such as decreasing the measurements so you don't need as much fabric or removing some of the detail. This all needs to be updated on the tech pack. Then, during the fit process, you'll update the measurements chart several times until you approve a fit sample.

Why you need a tech pack

A tech pack is the starting point for getting your garment manufactured. It provides all of the key information that will determine things like the cost of the garment, what fabrics and components will need to be sourced and how long it will take to make. This document gets you to the first stage of production. It also allows you to get a cost price from different manufacturers and give them the opportunity to source the best fabrics and components, prior to making a call on which factory to use. This is beneficial because the factories will often quote a better price when competing against others and also because it means that several people are out looking for the fabrics and trims you require, so you have a better chance of getting exactly what you want at the best price. For those of you who aren't looking at factories, just a really small quantity produced by a sample machinist, this document will still be very important, but used slightly differently. The pattern maker will use the measurements to create the pattern and the machinist will refer to the construction notes, as a factory would. The fabric and trims section will be useful for you to make a note of who is supplying what and keeps a permanent record for you to refer to when completing any documentation, or responding to any queries on your product.

Having a tech pack allows you to keep the fit of the garments consistent across your range. Have you ever been into a shop and tried on several things, to find you're a size 8 in some things and a 16 in others? Annoying isn't it. Good tech packs allow you to control the measurements of your styles and make sure they are relevant to your customer. As time goes on and you learn more about your customer and their preferences, you will be able to create the measurements of your ideal customer, which will help you with fittings in the future (this is quite a complicated topic and something I'll go into on another post, after I've covered the basics!). You may notice that the sizing of some companies is more generous than others; this is due to companies having a different version of their ideal customer. This is another reason why tech packs and fit sessions are important, there's no such thing as a 'generic size 16', for instance, in retail and you need to figure out what is suitable for your customer.