Placement Prints vs All Over Prints and How They Affect Your Fashion Manufacture

One of my most popular posts is about 'Strike Off's' and how they're important when using print designs in your fashion range (you can read it here if you'd like). Another key part of the print process is deciding if you want to use a placement print, or all over print (known as AOP). In this post, I want to explain the differences between the two and how the process varies slightly.

Keep in mind that whichever process/style you decide, you'll always need to have a strike off produced.

👉 By the way, if you're into behind-the-scenes gems like this, you'll love my Designer Diaries newsletter - packed with tips like this. Grab it free here >>>

What is an all over print, or AOP?

In this case, in the first instance it's as simple as it sounds. An all over textile print basically means that the print is all over the fabric, rather than just printed on one portion of the garment. It get's a little more tricky though as an AOP print can be placed. To explain;

An all over print is most often printed directly onto the fabric, before it is cut and made into a product; you print the whole length of fabric. There are some options for printing an AOP directly onto a finished garment, but I wouldn't usually suggest this, as it's very difficult to do perfectly. A length of fabric is flat and much easier to print than something 3d (like a garment). I often see that when a garment has been printed, there's gaps in the print and the base colour of the fabric can be seen.

To use an all over print, you need to have your print design artwork formatted as a 'repeat'. The artwork should align seamlessly on all sides, so that no lines are visible when the design is printed. Creating repeats is a very specialised skill, so make sure that when hiring someone to create a print for you, they have specific experience with textile repeats. Someone who has other types of experience, for instance a graphic designer or clothing designer, won't be as well placed to create the repeat. Likewise, someone who has textile design experience but only with placement prints, may struggle to get the repeat correct. There's a lot of considerations when designing an AOP print and the repeat itself isn't just about the way the print lines up, but also about the spacing and layout when the design is put together.

Typically, an all over print design would be used like any other fabric; it would be cut in the most economical way and sewn together. However, there are a couple of options that you might want to consider, for an AOP print;

You might want the print to match up at the seams. Particularly if you have decorative seams going down the front that will be really obvious, or if you have a large scale print which will look odd if the prints don't match up.

You might want to request a specific position for the print. For instance, you might want each garment to be exactly the same, so you'd ask for the print to be in the same position on each item. Or, if you have a print that has a spcific look, you might want to ask for a specific part of the print to be placed in a particular area of the garment. You would need to provide the factory with a technical drawing to show the position, along with a detailed description.

Keep in mind that if you ask for a specific placement, this will increase your costs and also make the fabric usage less economical, so it's worth thinking about how important the placement is to you.

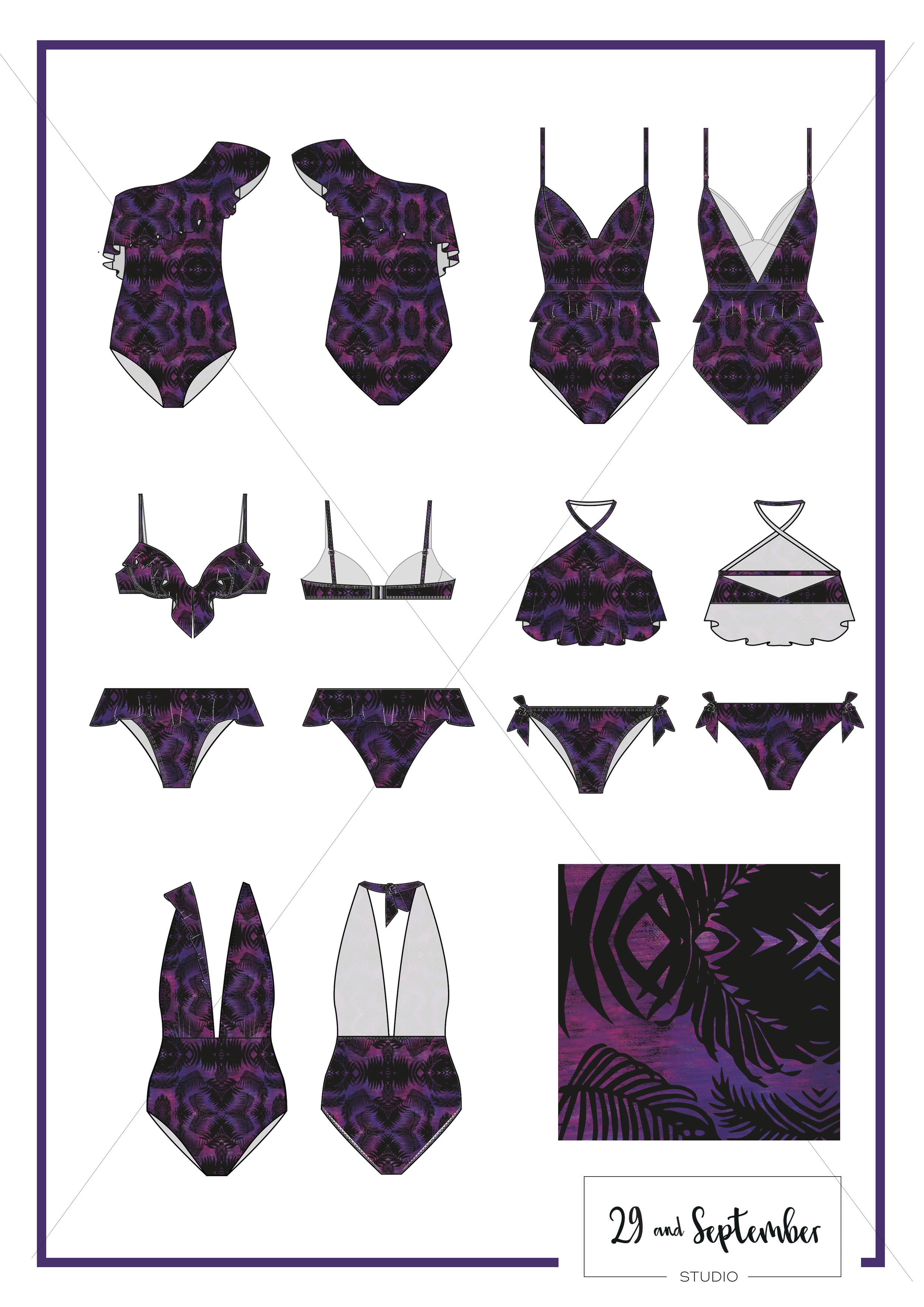

An example of an all over, or AOP print

An example of a seamless repeat print I created

What is a Placement Print?

A placement print is usually applied to the fabric after it has been cut and/or made into a garment. It's not usually printed directly onto a length of uncut fabric (although occasionally this does occur). The artwork itself is sized correctly and is stand alone; it doesn't have to line up with anything else, or be seamless like the AOP print. Things you'll want to consider for a placement print are;

Where will you place the print? You'll want to create a technical drawing which shows the placement of the print, alongside specifications like the measurements of the artwork and also to indicate the position.

You'll need to carefully consider the size, to ensure parts of the print aren't cut off when the pieces are sewn together. Or, if you're printing onto an existing garment, you want to avoid printing over seams as this can be difficult to achieve with a high quality finish.

If you have multiple placement prints on one garment, it's usually best to provide a separate artwork for each, rather than put everything in one file.

A placement print is often quite a manual job, depending on the method used, so be aware there may be some inconsistencies due to human error in the process.

You can see some examples of placement prints below;

Placement prints I created for Griarte apparel. Their products can be purchased here; www.griarteapparel.com

General considerations for prints with a specific placement

Remember, this could be a placement print, or an AOP print where the placement should be on the same point for each garment.

Typically, because this is more manual and time consuming, this will be more expensive than an AOP print that can be cut out like normal fabric.

Keep in mind different sizing. Normally there are costs associated with creating different sized artworks, so you might find you have to use the same size print for all of your designs. Therefore, this will cause variation in the overall appearance of your designs. For instance, if your smallest size is an 8, you might find that your placement print gets cut off a bit, because the garment is a lot smaller than your sample size. So make sure you check placement prints on every size you're making, before you commit to the final order.

💌 Love this kind of no-fluff, high-value advice?

Then you’ll definitely want in on my weekly newsletter - Designer Diaries. It’s your behind-the-scenes pass to growing a fashion brand without the overwhelm. Think bite-sized strategy, creative inspo, and the kind of real talk your business actually needs.

Pickleball outfit inspiration……